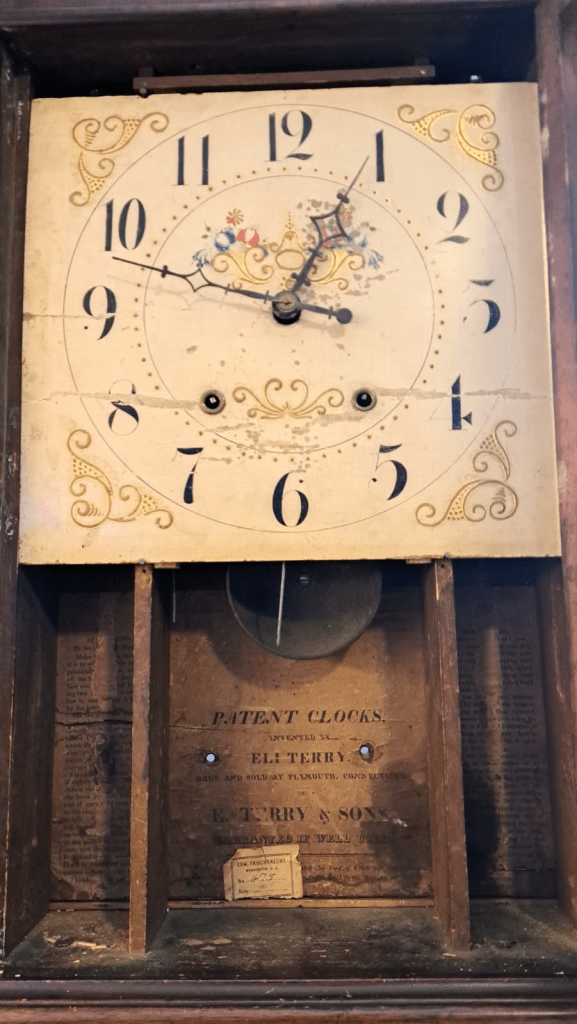

Here is a beautiful Pillar and Scroll clock, likely dating to the 1820’s or 1830’s. Eli Terry innovated new ways to produce wooden works clocks, achieving the first mass-production with interchangeable parts. Several very clever design and production details made this clock affordable to more people than previous brass-movement tall case clocks were.

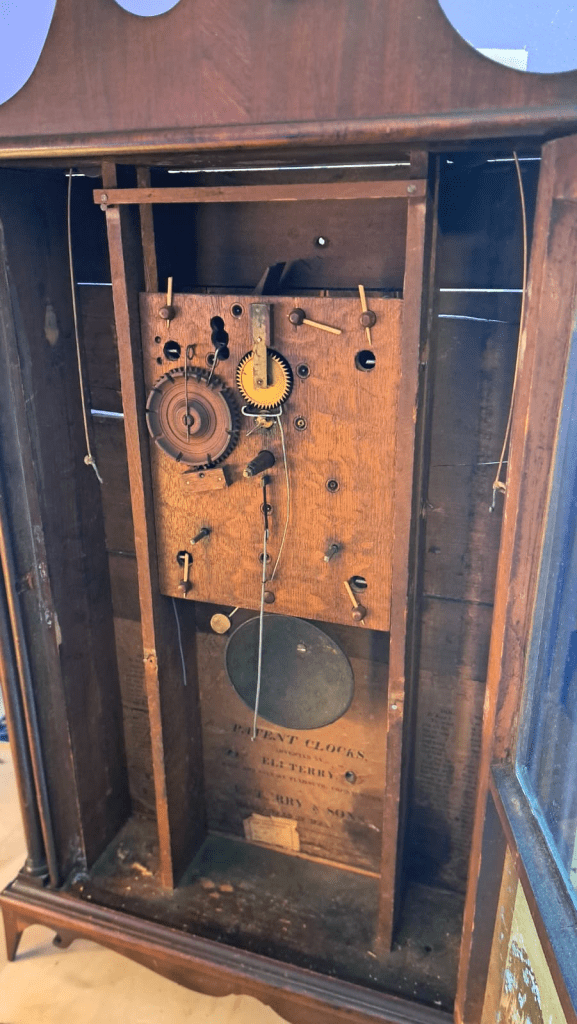

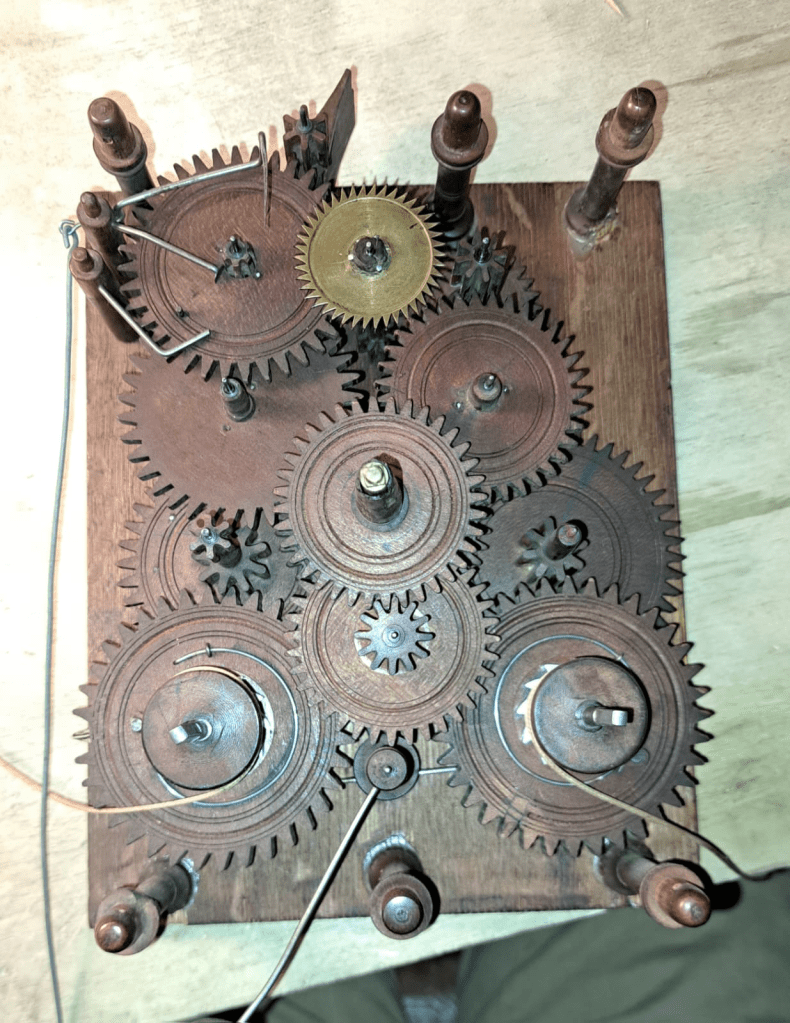

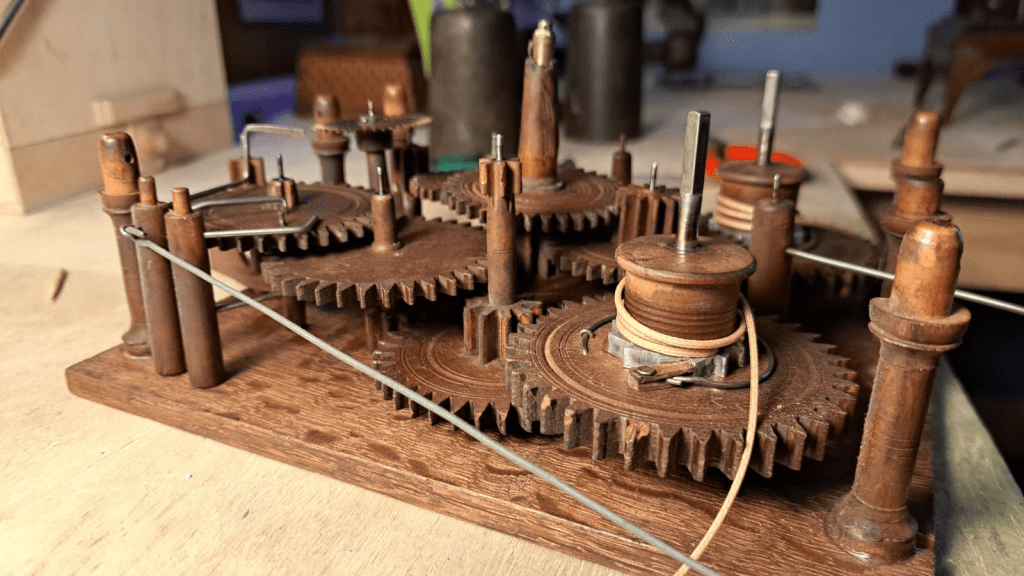

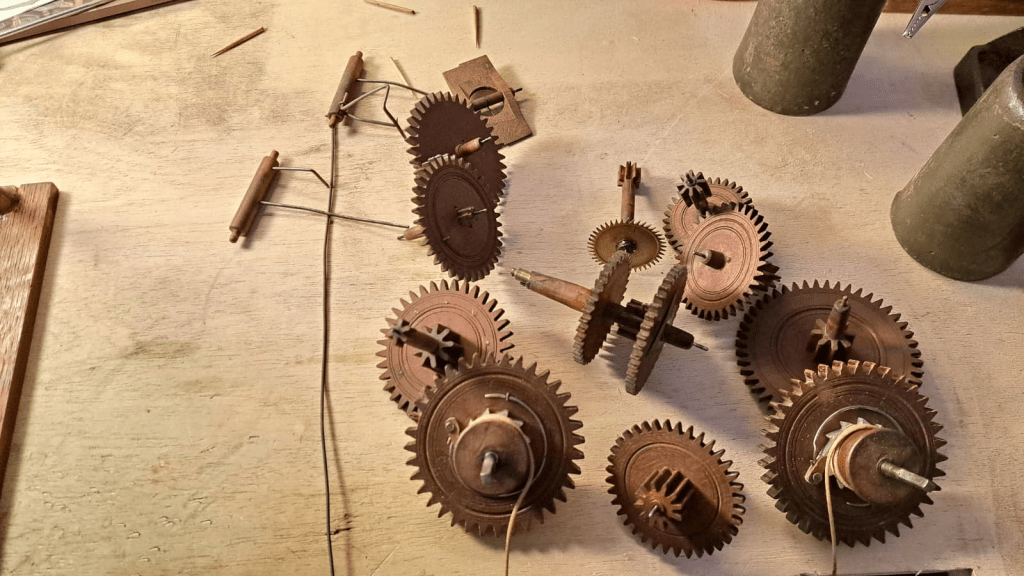

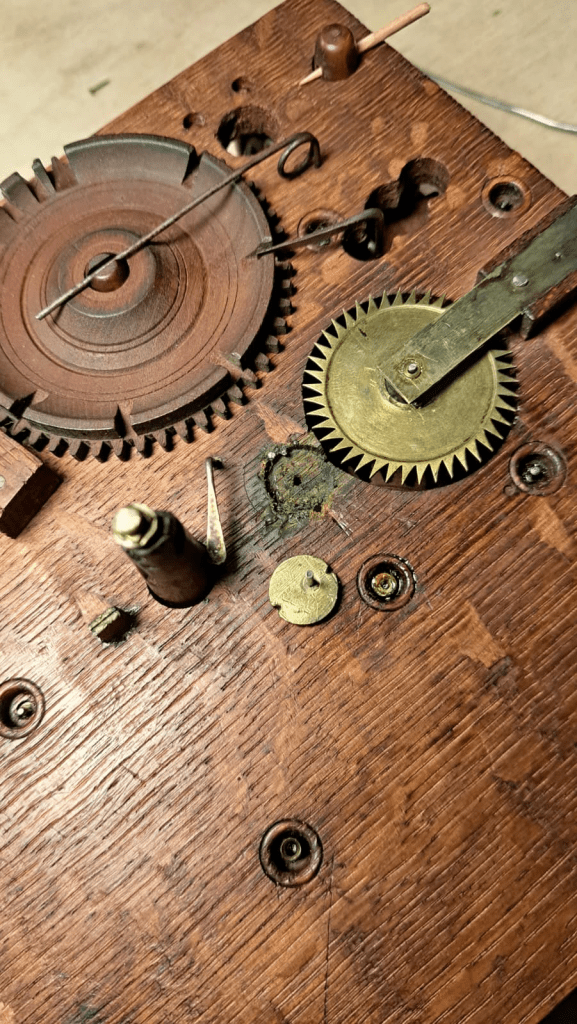

Our first look at the wooden works or movement. It has two gear trains, one for keeping time and the other for striking the hours. Each train is driven by a weight and should operate for around 30 hours.

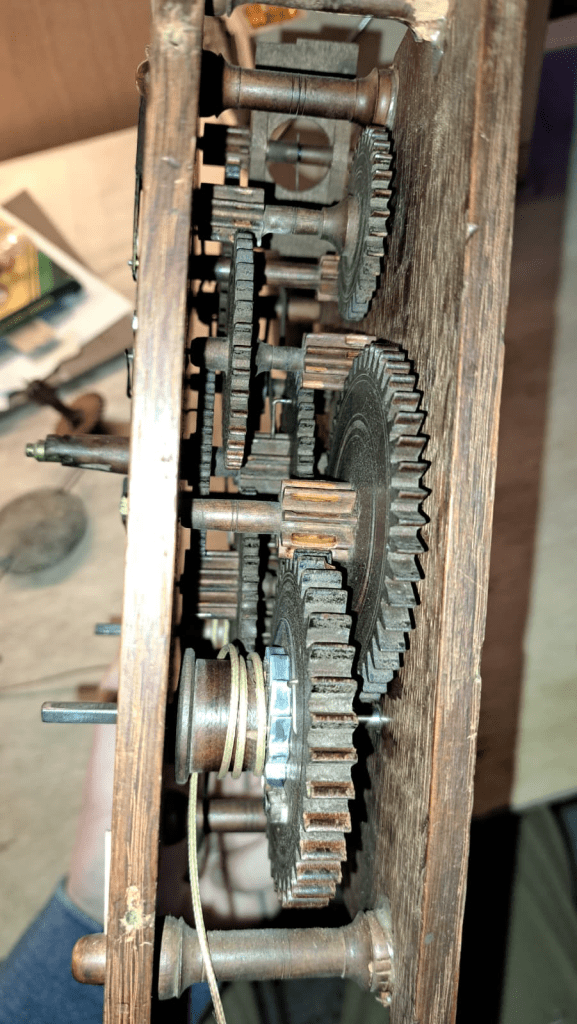

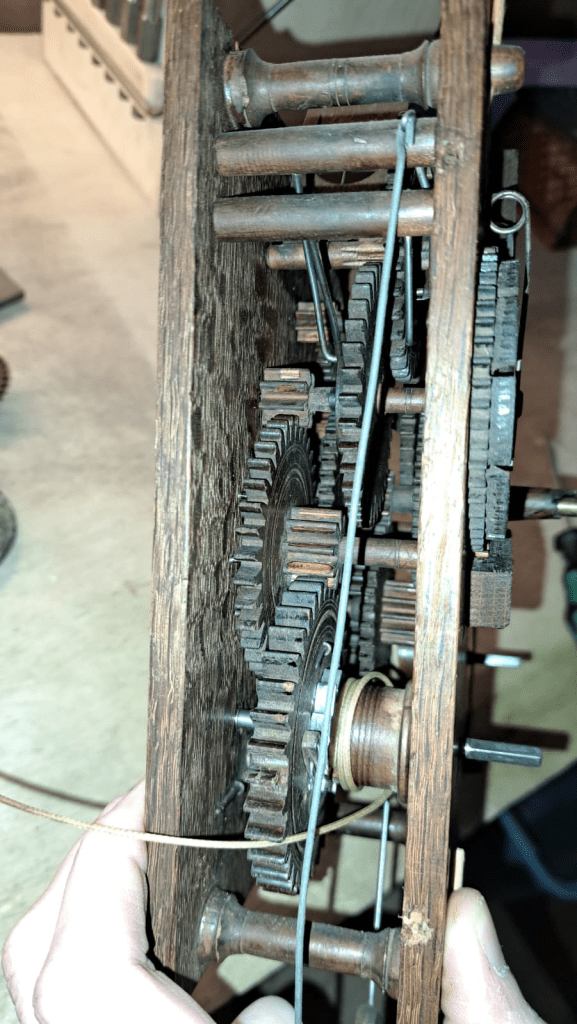

By the time of this clock, Terry had refined the design to have a real economy – and I think elegance – of parts. The plates, wheels, pinions, and arbors are all wood. Originally, only the pivots and escape wheels were metal, but a previous repairer has given this clock brass bushings:

The plates are likely oak, the wheels cherry, and the arbors were often maple, birch, or laurel. To my eye, the wheels and arbors on this example appear to both be cherry.

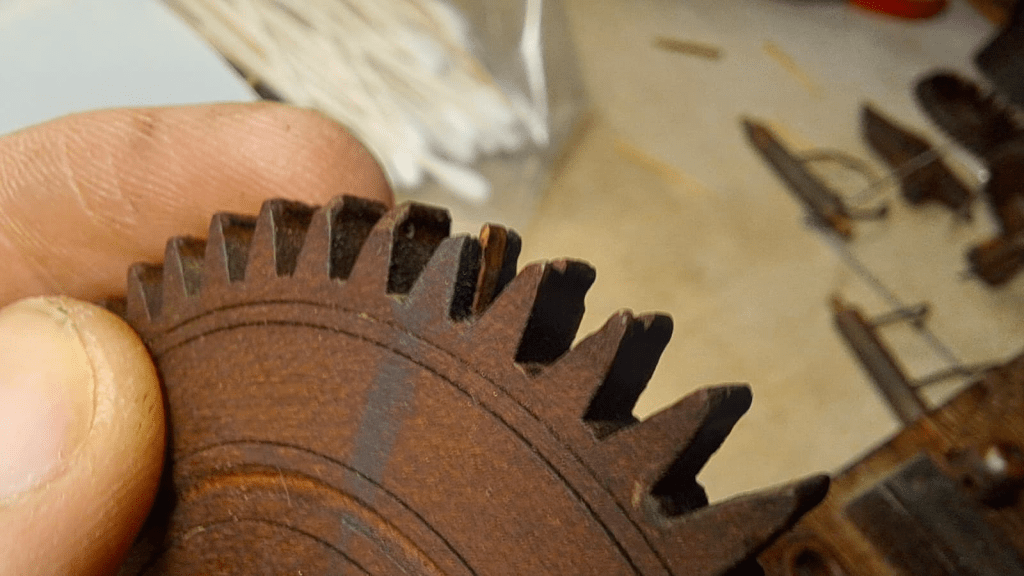

I inspected every part and while this clock has plenty of wear, it has also been well-repaired and nothing is seriously damaged. The hour horn is missing significant sections, but it is stable and still works as it should, so I left it alone. Below are two examples I found of replaced/fixed teeth:

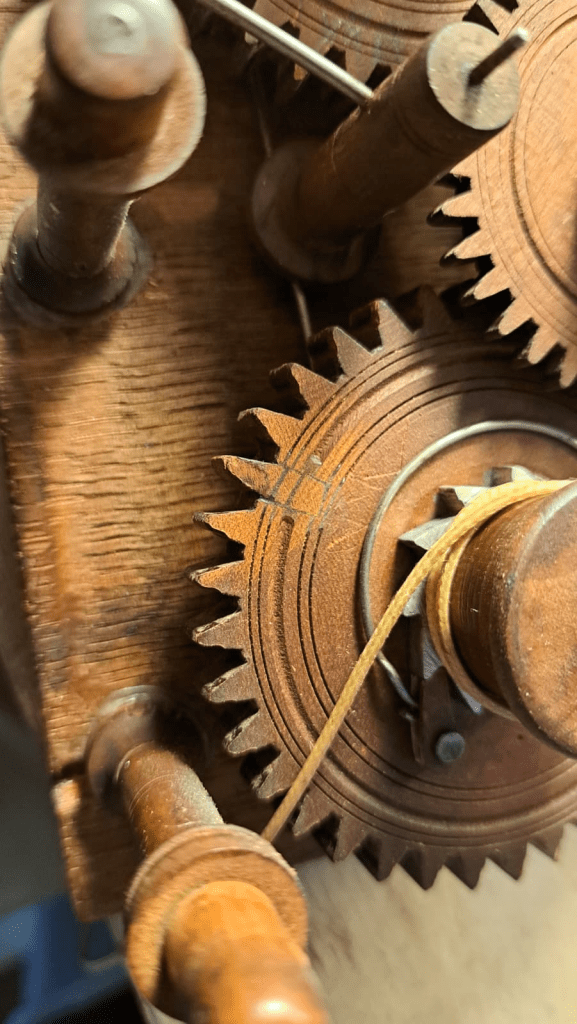

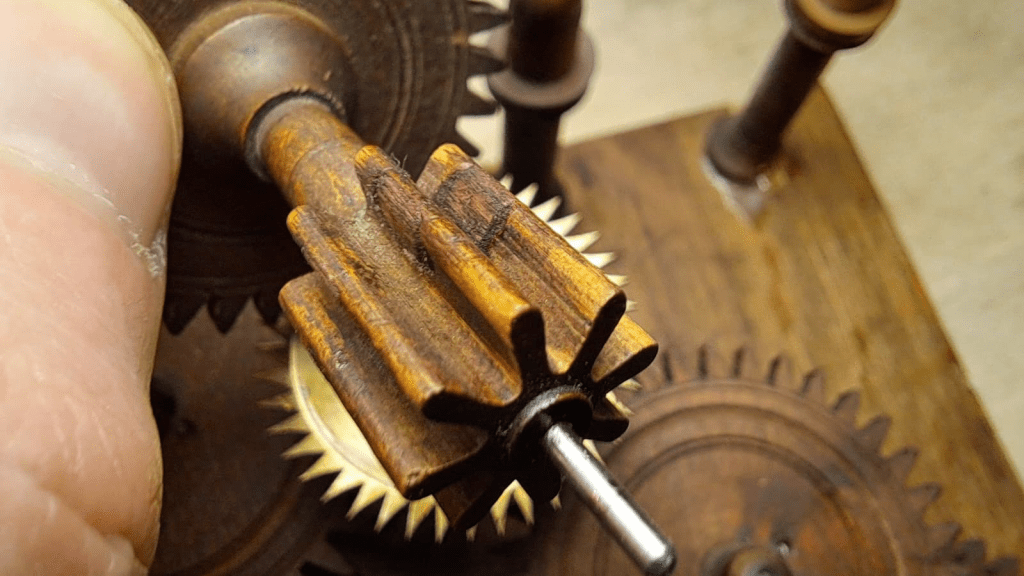

Looking at the profile of some teeth, we can see that it was cut by a machine, with two saw cuts producing the correct geometry. To account for expansion/shrinking of the wood, the teeth on these wheels and pinions mesh with plenty of overlap and clearance.

After I assured everything was sound and stable, I cleaned all the pivots of old gunk and grease.

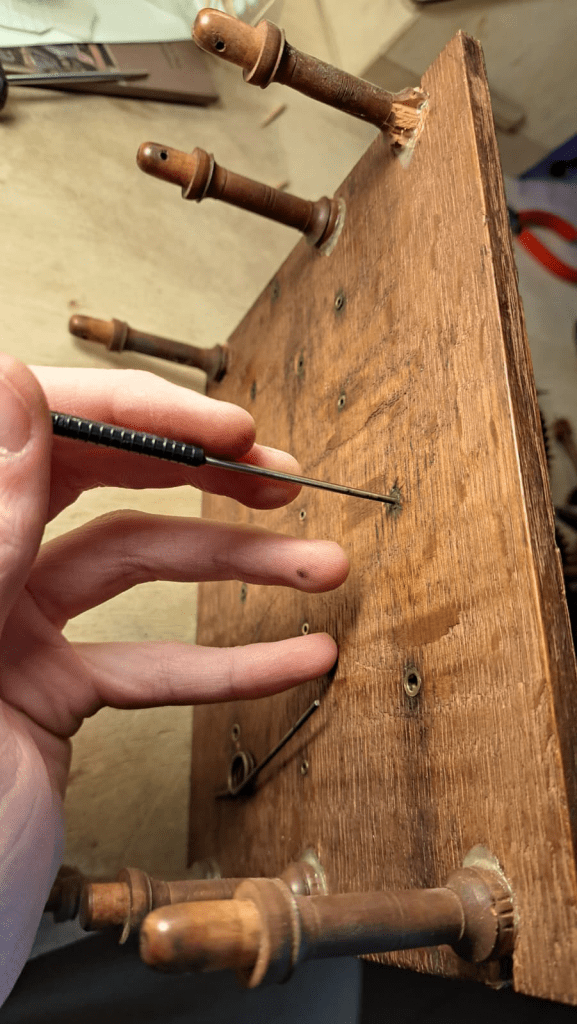

Then I cleaned the pivot holes in a three step process:

Then I reassembled, oiled, and tested the strike and time train. I sequenced the strike side in short order and was pleased with it, but the time side gave me some trouble both in the escapement and the transfer of power in the train of gears.

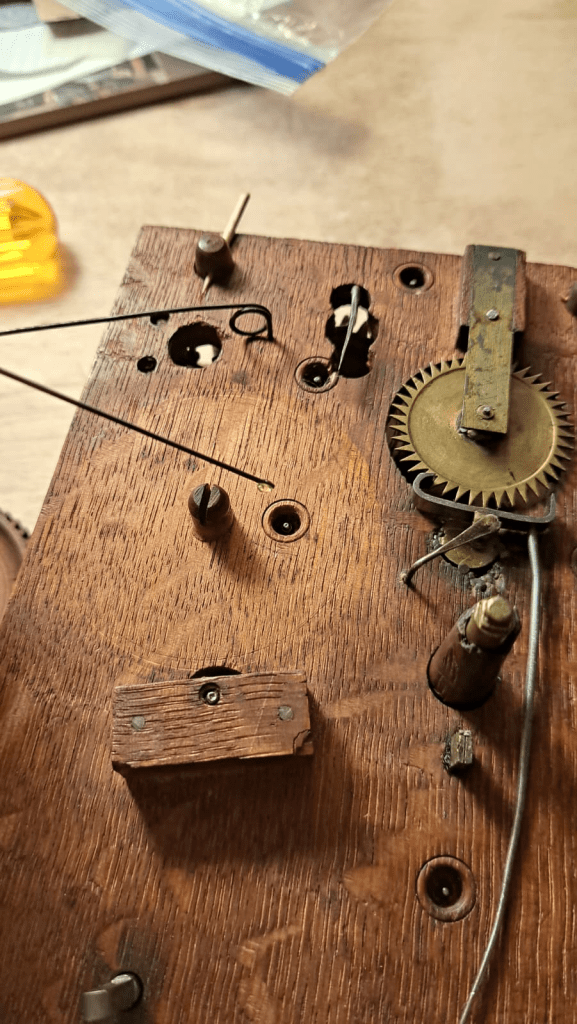

To fix the escapement I first reground and polished out the grooves. The old grooves were also worryingly close to the edge, I addressed that later by seating the anchor more fully in its pivot.

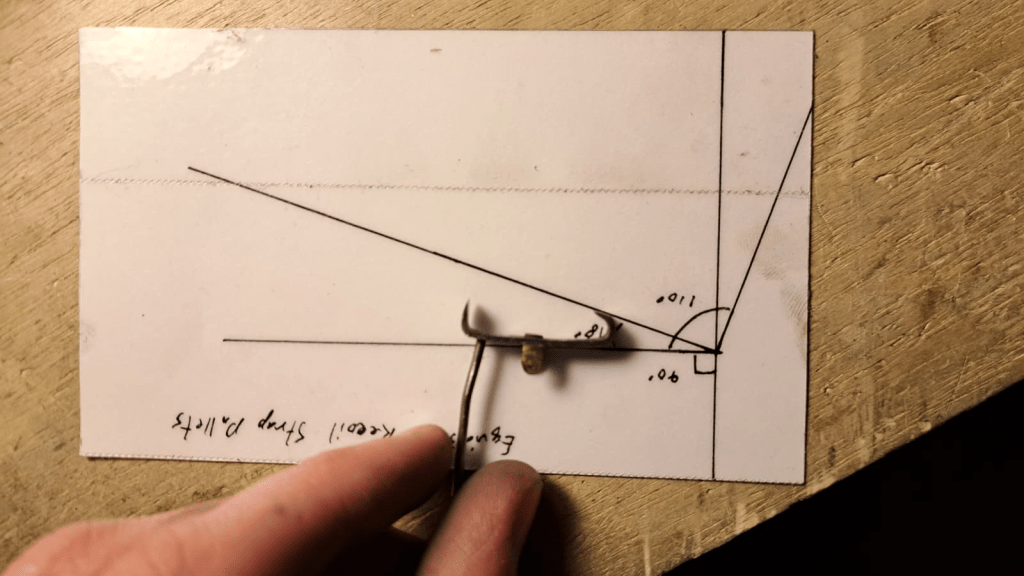

Then I refined the angles of the pallets using the method taught by Jerry M. Faier CMC:

Adjusting the drops and locks took some care and included re-seating the anchor pivot post. Terry brilliantly designed these clocks so the escapement is outside the plates and the anchor pivot is easily adjustable like this, which makes assembly, fit, and repair much easier.

I removed the old nails, and since the wood at those spots was so punctured, I filed new slots in the post for nails in different locations, that way it re-attaches more securely.

It is neater, and I needed to adjust the pivot-to-pivot spacing of the escapement and anchor anyway.

I straightened the escapement wheel teeth as best I could. In the end the wheel must have some acentricity, because I could only get an even beat for part of its cycle.

The more difficult problem to diagnose was why the train kept stopping after a couple minutes. Somewhere the gears were binding a little too much… Eventually I suspected the fourth wheel pinion was too worn.

To fix this I opted to glue slivers of wood into the worn dents.

Then I carefully sanded and filed them to the correct profile.

I was able to match the original leaf profiles pretty well:

Finally I stained my repair:

That did the trick and it now ticks a full day!

I also re-glued some veneer, secured one of the legs, and made the latch work again.

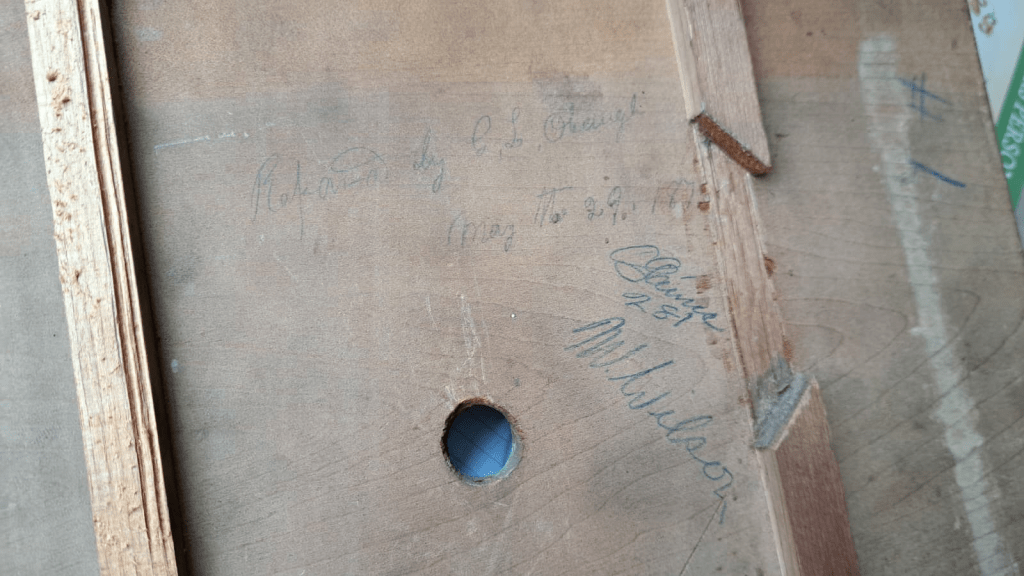

Now I can count myself among those who have cared for this clock:

Leave a comment