Ogees are my favorite (of the common clocks I see) to work on. Here’s a nice example I fixed for my friend Thomas. It had a series of small issues:

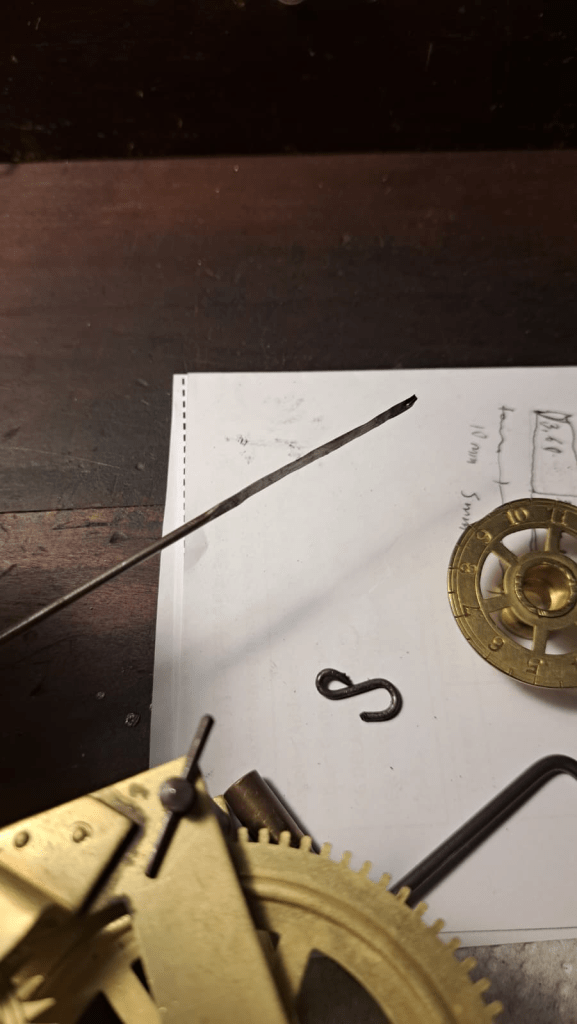

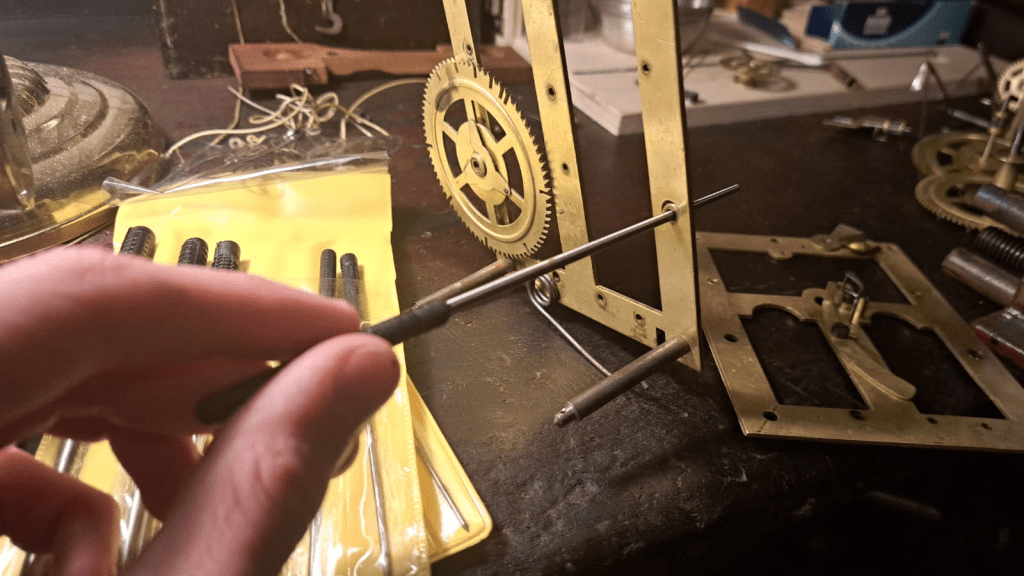

The suspension spring was bent and kinked. I was able to just straighten it out.

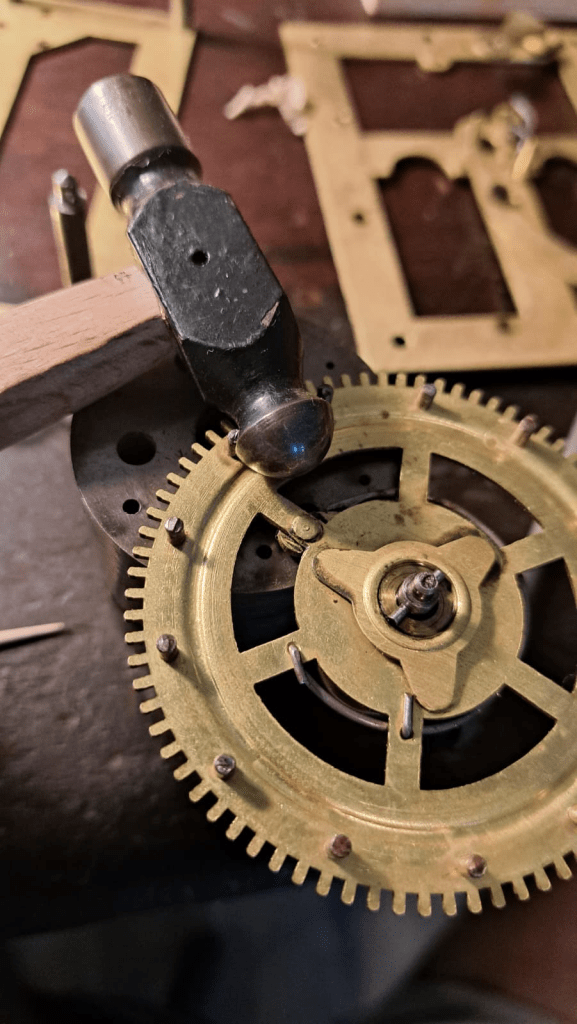

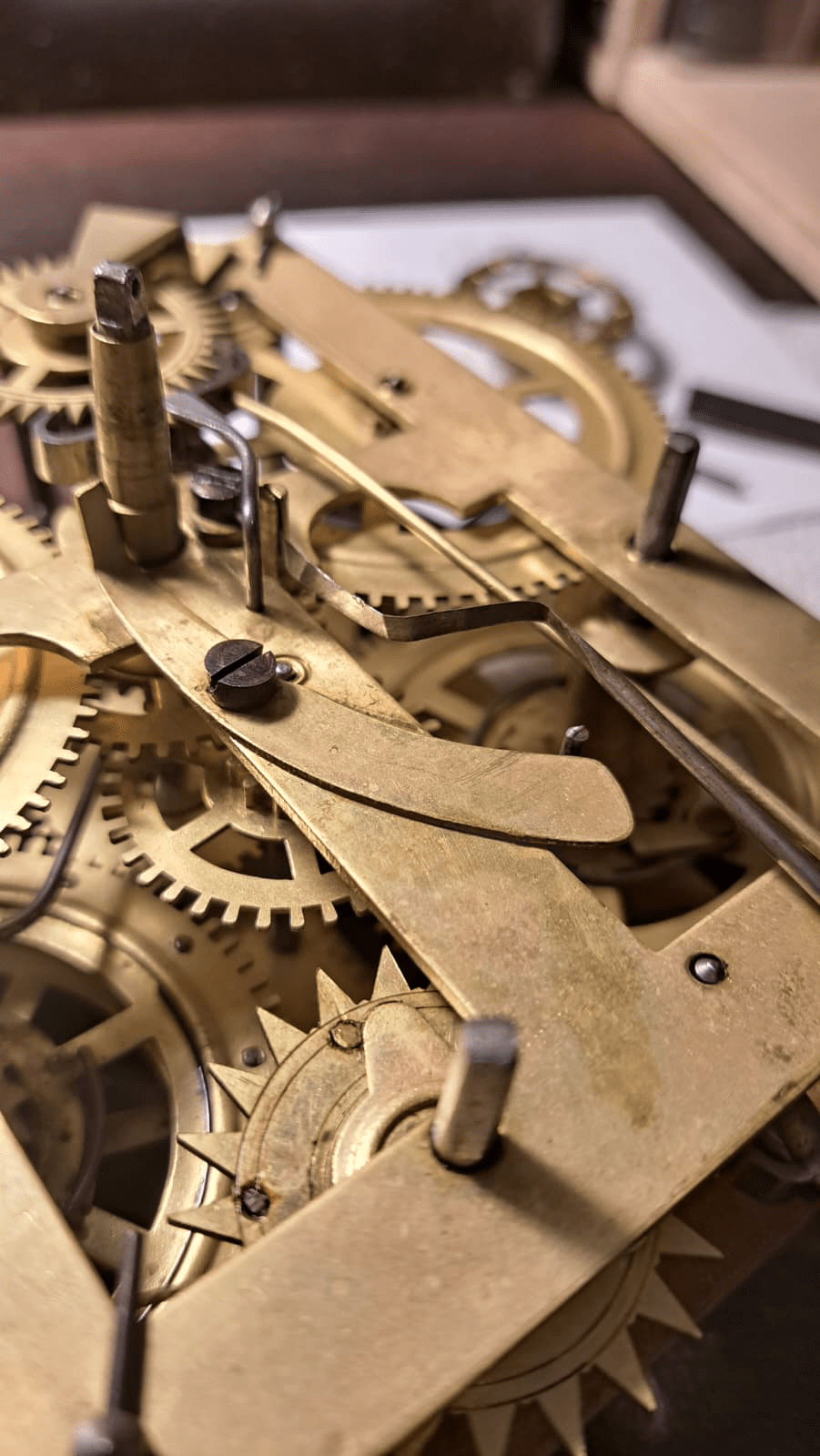

The escapement pallets had some wear in the form of grooves (see above). This indicates it has lived a good life. Let’s make sure it can live some more by polishing out the grooves (see below).

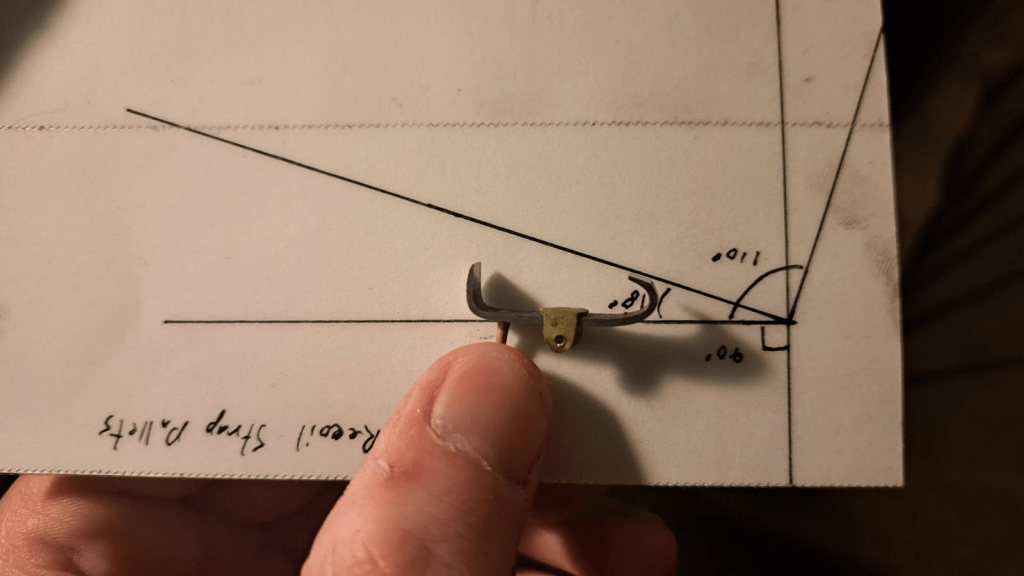

Then I checked the angles of the pallets using the method taught by Jerry M. Faier CMC:

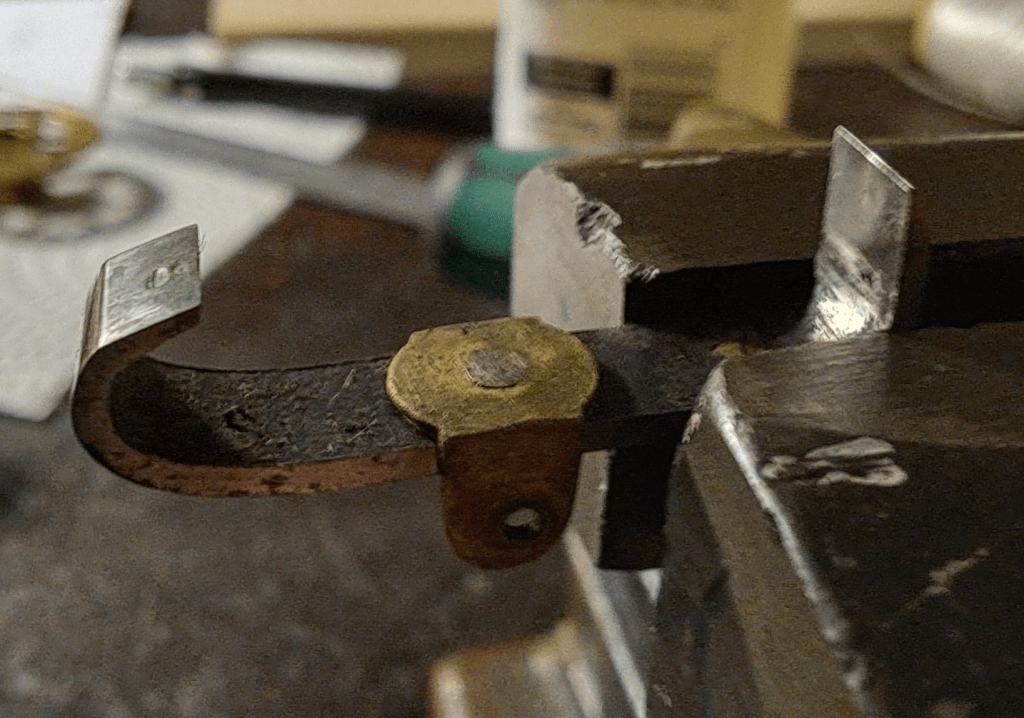

I noticed this click was very loose, so we’ll have to tighten that up. First step is taking the mechanism apart.

I re-riveted the click to tighten it.

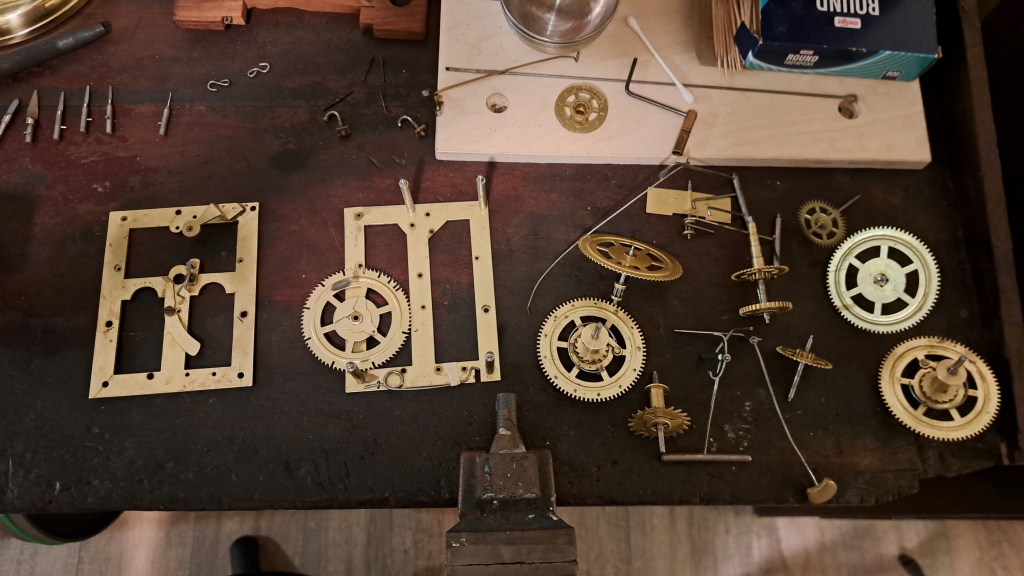

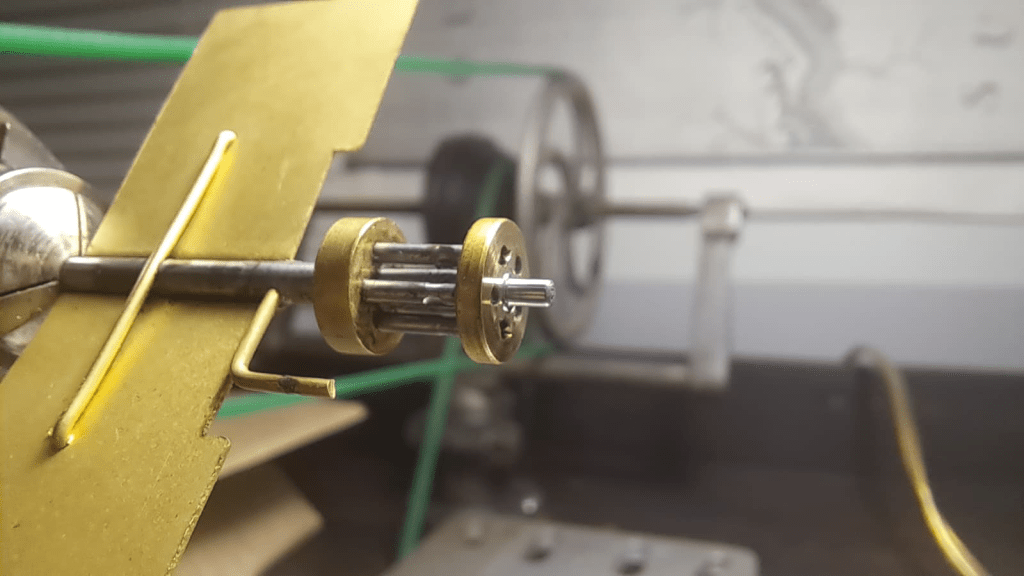

Next I polished the pivots on the watchmakers lathe (left), and smoothed the pivot holes with smoothing broaches (right).

While doing that I noticed this pivot was very loose in its hole. So I re-bushed it:

Then I spent some time adjusting the drops and locks of the escapement, so it would have a nice, fairly quiet tick tock.

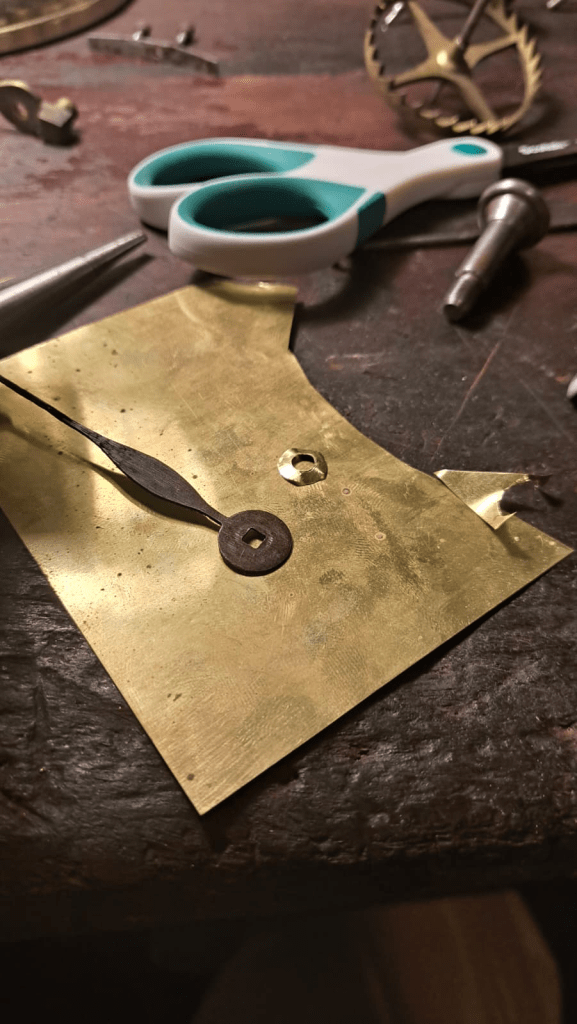

Finally I had some finishing touches to attend to. It was missing the cupped washer that holds the minute hand tightly. I do not have any on-stock; instead I made one from a sheet of brass. It was also missing a weight hook, so I made one using a nail (not pictured).

I am very satisfied and hope Thomas will enjoy it for years to come!

Leave a comment