The same thing that causes printers to break so often makes them worthwhile to take apart: complex mechanisms with moving parts.

I scored 3 printers at a dump recently and decided to record their yield.

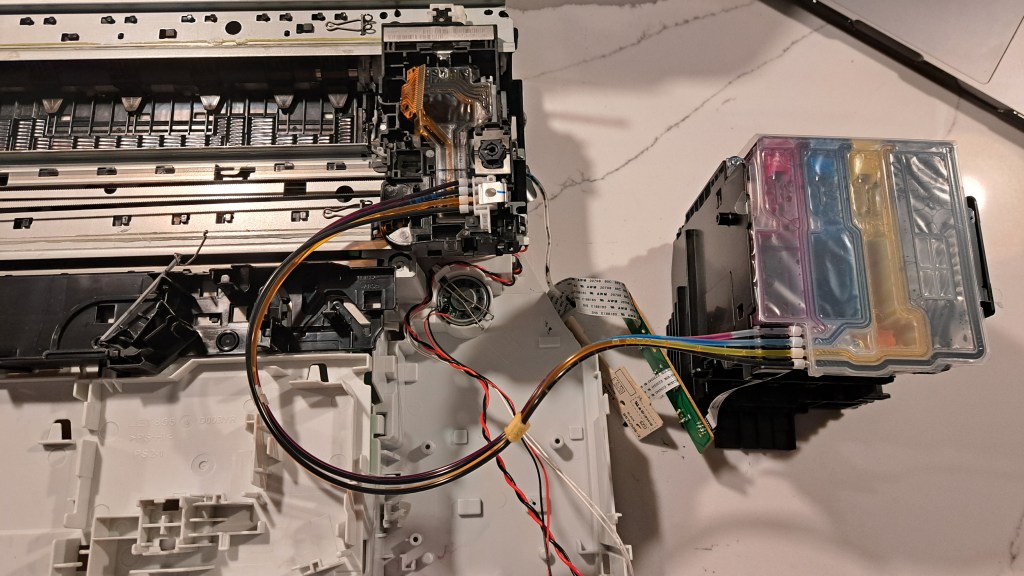

Cracking them open can be dangerous given all the ink.

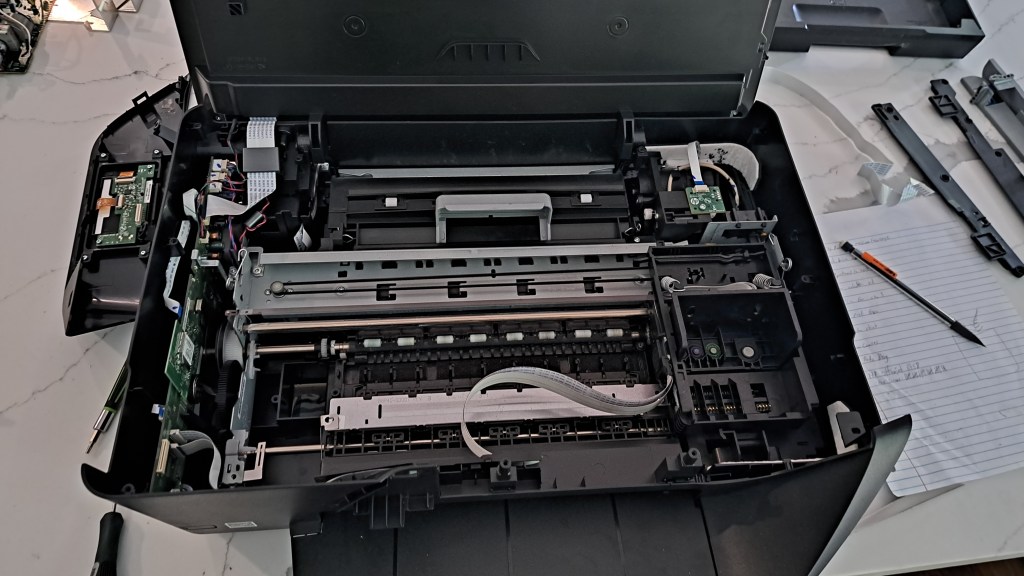

Engineers at HP and Brother still have not figured out a system for controlling the application of an inkjet that avoids a gantry of motors and pulleys. These are the most valuable bits, in my opinion. DC motors are always fun, and the gantry system often has a couple of nice stainless steel shafts.

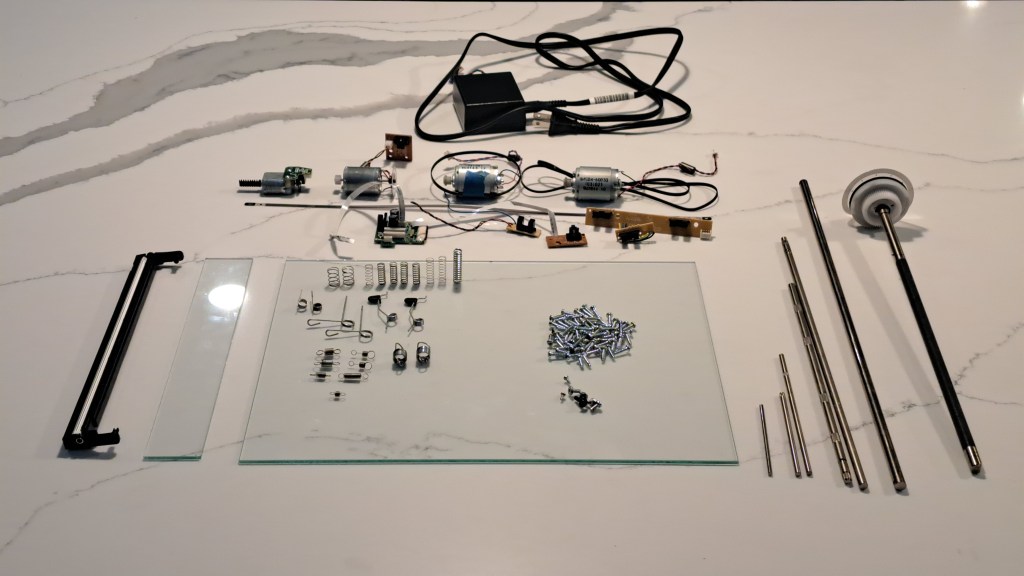

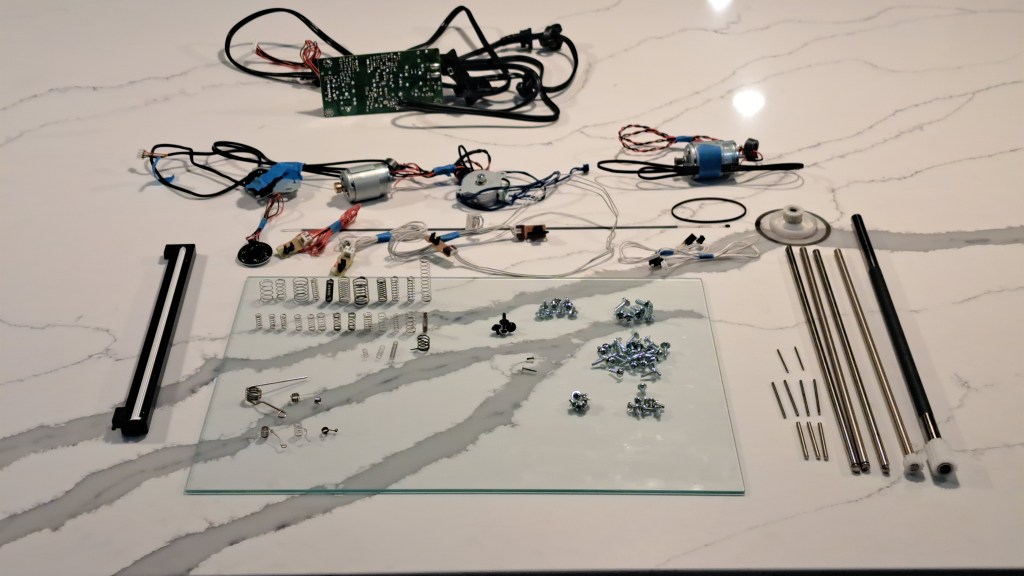

THE YIELDS:

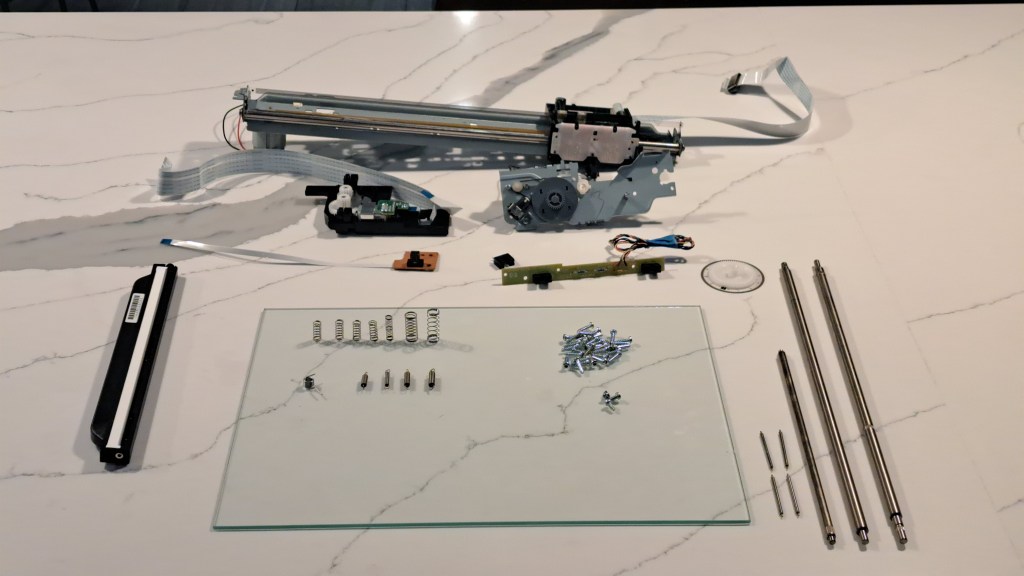

HP Officejet 6958:

- Screws (Hex): 76

- Big shafts: 4

- Small shafts: 3

- Motors: 4

- Compression Springs: 10

- Tension Springs: 9

- Torsion Springs: 6

- Sensors: 6 (+2 on motors)

- Glass Plates: 2

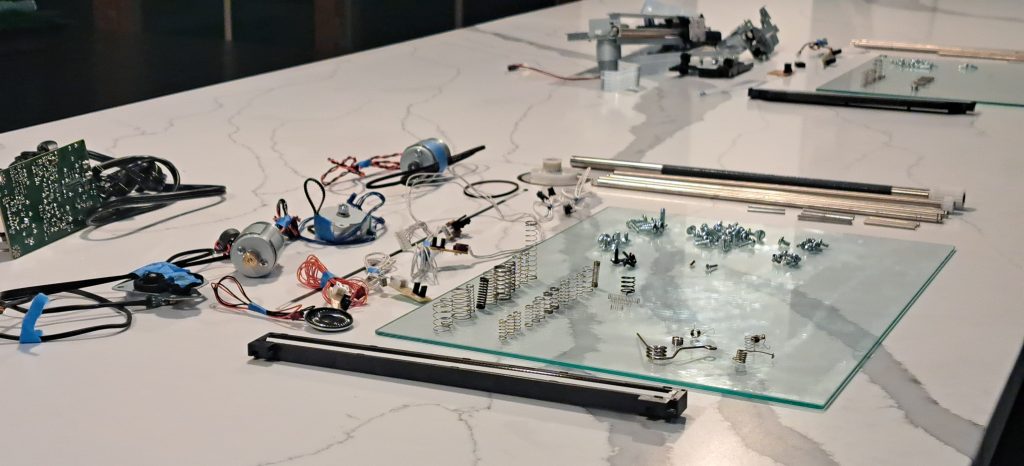

Brother Work Smart Series Model Mfc – J995DW

- Screws (Philips): 70

- Big shafts: 5

- Small shafts: 9

- Motors: 4

- Compression Springs: 29

- Tension Springs: 0

- Torsion Springs: 5

- Sensors: 4 (+2 micro switches)

- Glass Plates: 1

HP Photosmart C4480:

- Screws (Hex): 35

- Big shafts: 4

- Small shafts: 4

- Motors: 3

- Compression Springs: 7

- Tension Springs: 4

- Torsion Springs: 1

- Sensors: 5 (+1 on motor)

- Glass Plates: 1

IN TOTAL:

- Screws : 181

- Big shafts: 13

- Small shafts: 16

- Motors: 11

- Compression Springs: 46

- Tension Springs: 13

- Torsion Springs: 12

- Sensors: 18 (+2 micro switches)

- Glass Plates: 4

That’s just the stuff I thought was worth saving/recording.

I also saved the power supplies.

Of special note is the optical sensors that these devices use to record the positions of motors/gantries. I’ll probably do a follow-up post about how these work [out now!], but they accompany a ribbon or disc that has a series of opaque and translucent portions. I think these could also come in useful, aside from just being a cool device to explore.

Well, I had fun reducing these carefully engineered, optimized for economy rather than operation, machines down to a few useful components.

(Now I’m gonna put those components, some ink, and hunks of plastic in a box, shake it around for a while, and witness the birth of a whole new printer. Life is miraculous…)

Leave a reply to Scoping Out Optical Encoders – What Will Makes Cancel reply