This is a clock from the 1850’s-1860’s that has quite a peculiar case – a painting! On a scene of the Rhine river, a painted clock tower holds a real working clock.

The painting itself is quite discolored from time. It needs a good painting conservation, but I’m not the person for that job.

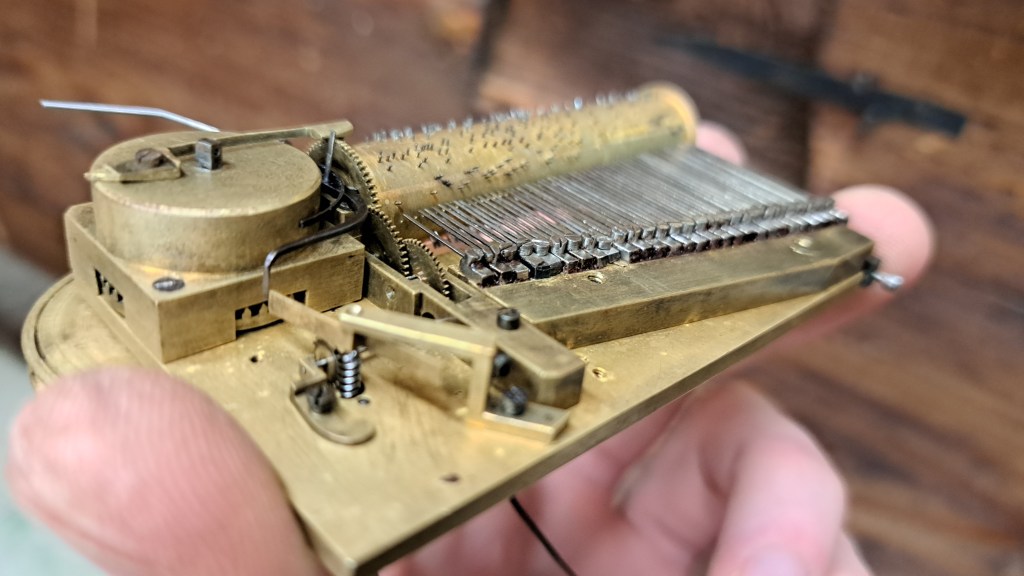

The painting is not on canvas but a thick wooden board which has a cut out for the clock and a music box. The music box had previously been cleaned by someone else, but, as I found out, it needs some more work for it to play nicely with the clock movement.

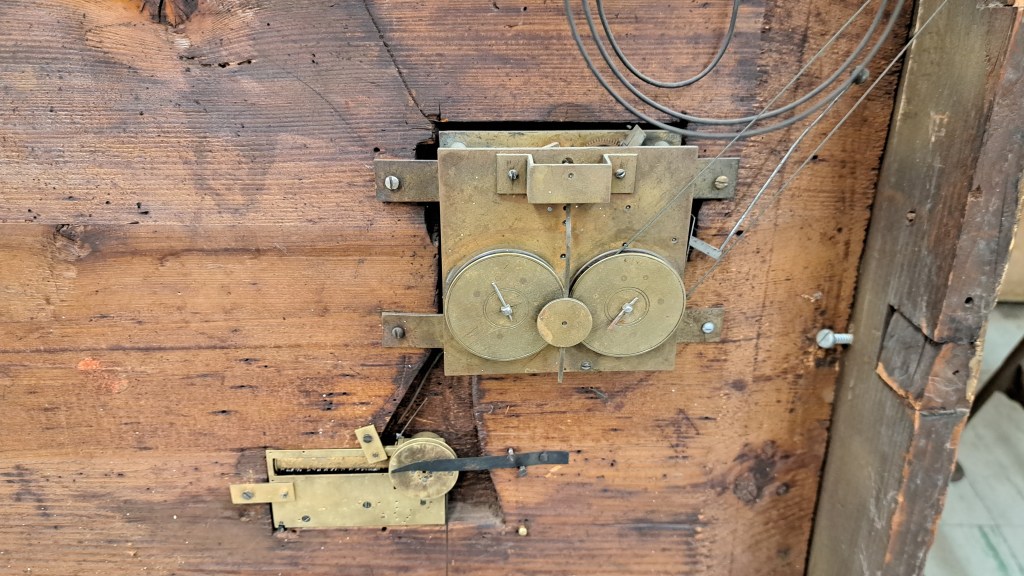

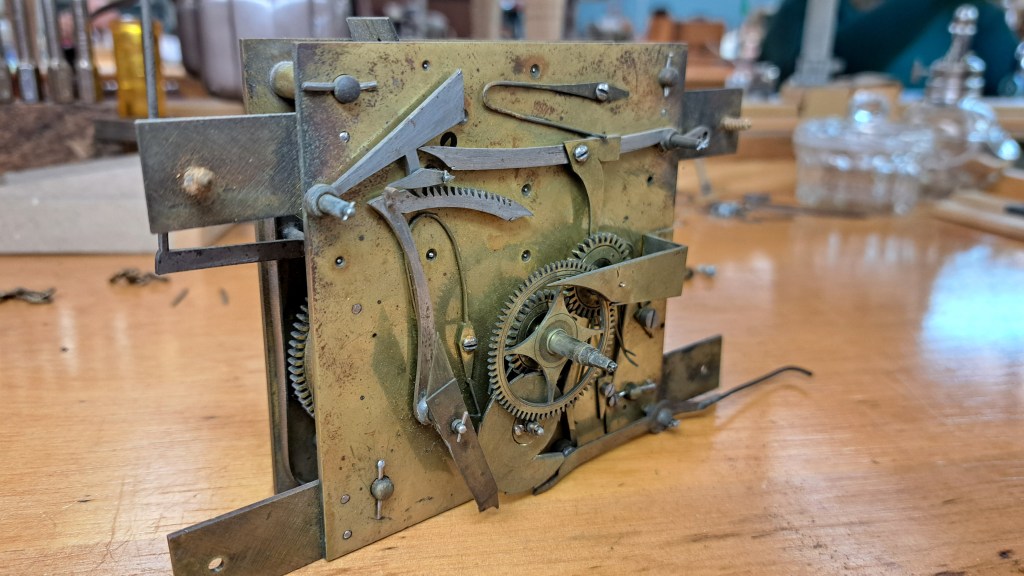

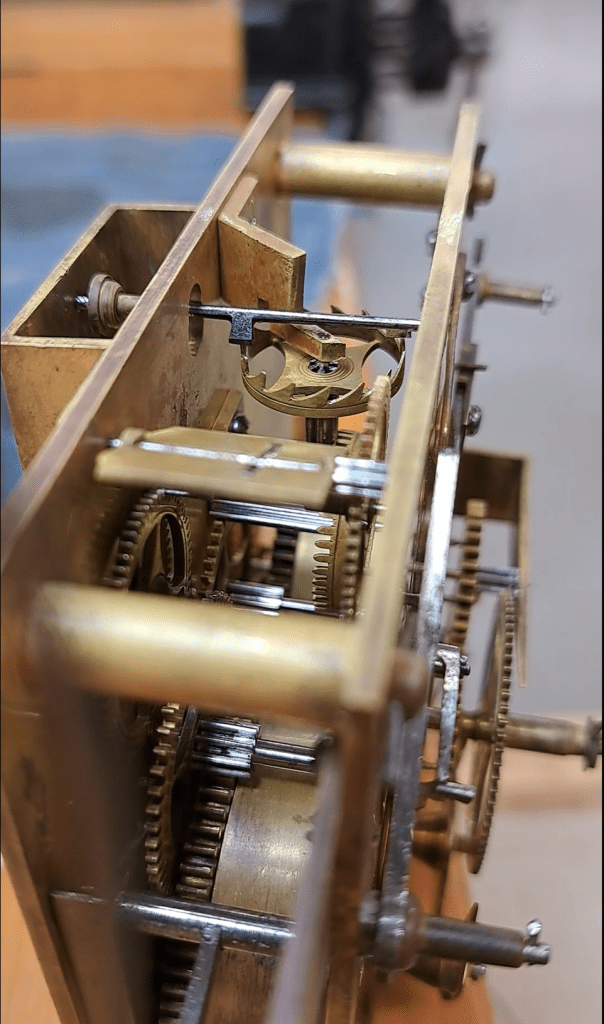

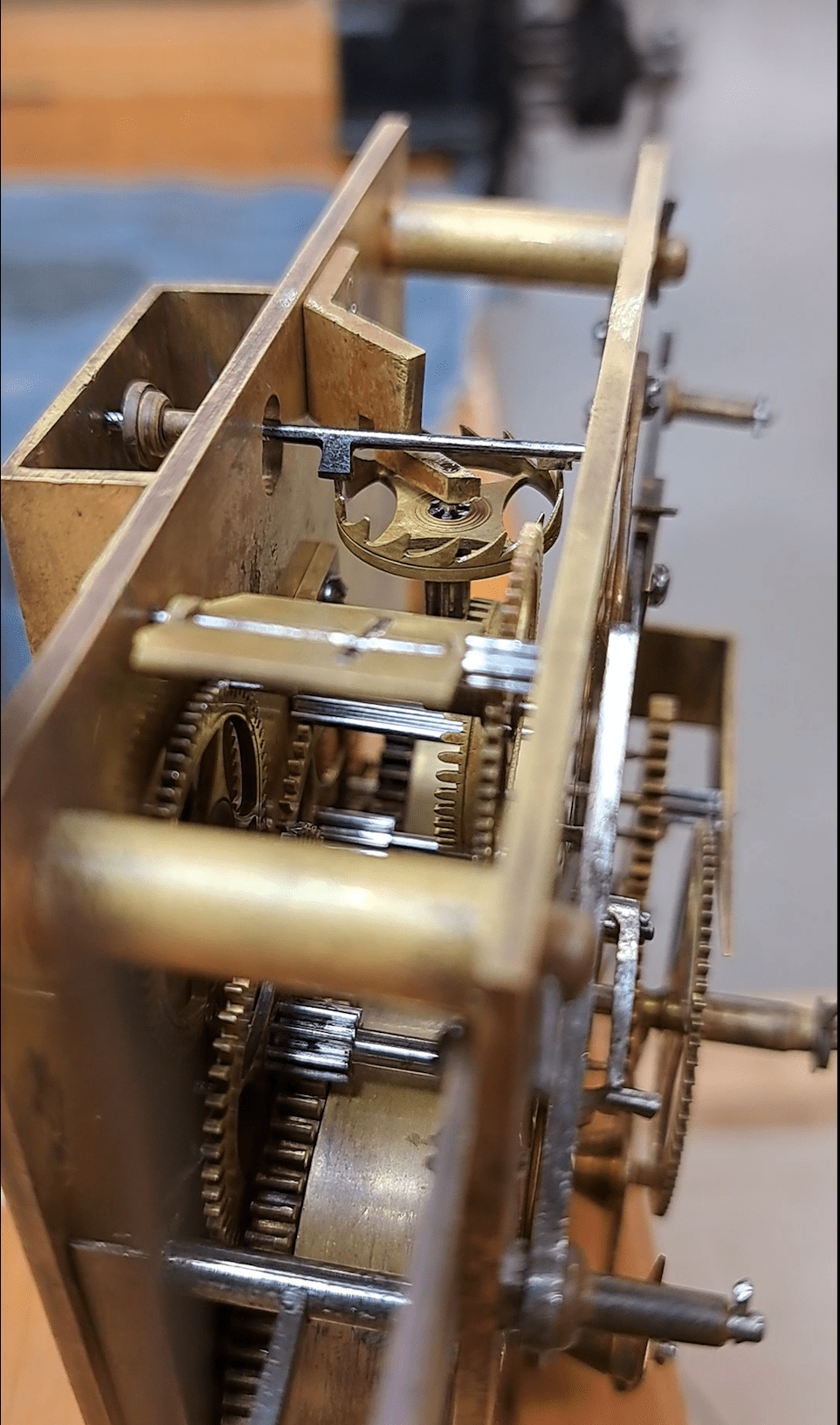

And removing the movement from its case/painting, here’s our first look at the verge escapement. That spiky wheel at the top is the escape wheel, or crown wheel as it is called due to its resemblance to a royal hat. Above it sits a rod, or in Latin virga, that has little posts on it that interact with the spikes of the crown wheel, causing a tick tock and pendulum to swing. The verge escapement is the earliest known type of escapement, and the one used for the longest time. They fell out of fashion right around when this clock was made, the mid 19th century, replaced with more accurate escapements.

Here’s a look at the front of the clock with the rack and snail for striking the hour.

I first pulled those pieces off the front and gave them a good cleaning before separating the main plate of the clock and getting into the inner gear trains.

Gave it all a good bath.

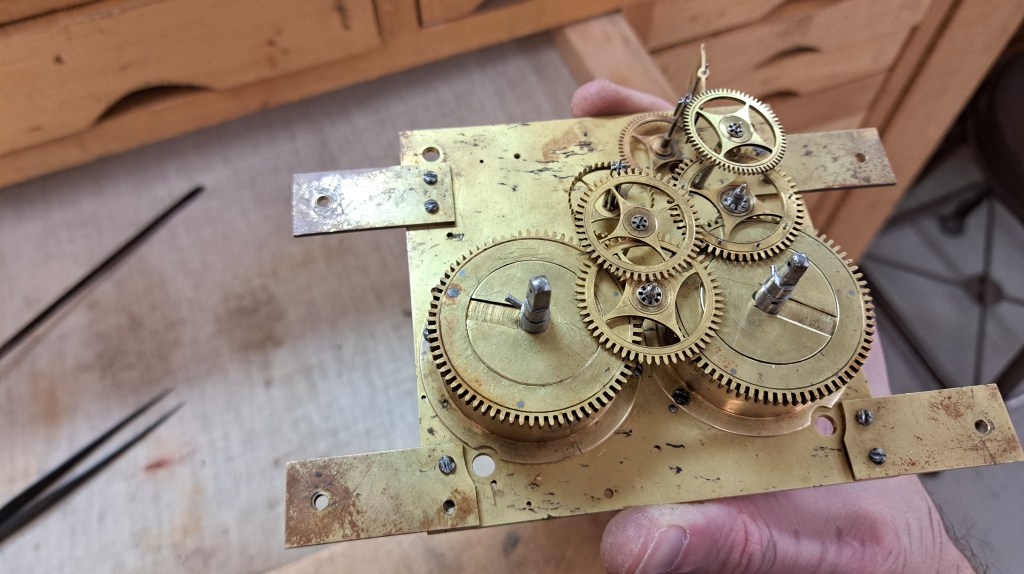

Here’s the inner gear trains. Fairly simply, just one train for time, going from the spring in the barrel on the left in the above photo to the crown wheel and virge (not in the above photo); and another train for the striking with the barrel on the right powering the wheel with little posts that cause the hammer to strike and up to the fly at the top right which keeps it from striking too fast.

I gave the mainsprings a good clean and re-oil. They attach to the arbors in a way I had never seen before: a slot in the arbor accepts the hooked end of the spring. Below is a better view of that.

I smoothed all the pivot holes. There was very little wear because the pivots are all hardened and thus don’t wear down and produce much grit. This also meant I did not need to polish or burnish the pivots. The hardened pivots, I believe, suggests this clock is French in origin.

Re-assembling it. Look how much cleaner it is compared to before.

The hour wheel had a loose friction fit so I crimped the tube to make sure it won’t slip when the clock is in motion.

And here’s it working. The crown wheel had some wear (one tooth in particular was lower than all the others), so it ticks a little inconsistently, but it stays running! I also had to play around with the levers on the front to get it striking nicely, apologies for not getting a video of the striking sequence.

The clock, when it strikes, also moves an arm that is supposed to signal this music box to start up. The issue is the arm coming off the clock moves left to right, but the music box wants a motion right to left. On closer inspection of the music box, it has clearly been re-configured and has some parts missing, so that’ll be a fun problem for someone else to solve.

Leave a comment