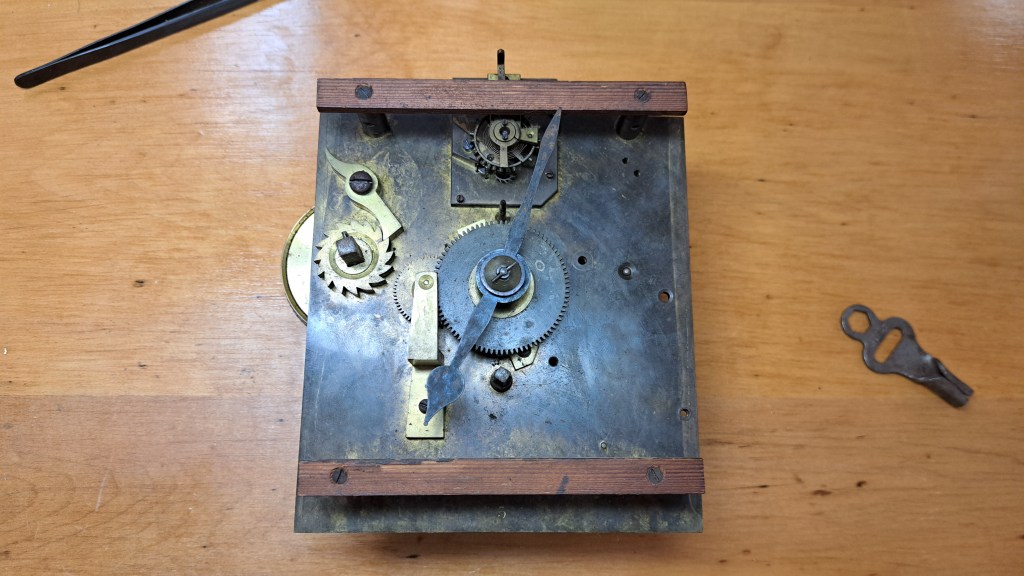

This is a clock with a fusee mechanism to regulate the power of the mainspring.

Looking into the plates, we can see the fusee on the right as a sort of conical spindle (fusee derives from the latin word for spindle, fusus). When fully wound, the rope that’s on the barrel in the photo is instead wrapped up the spiral length of the fusee.

Disassembly. This is quite a nice clock to work on because the parts are nice and stout. I believe it was in some sort of public space, like a train station, where a beefy, reliable mechanism would be important.

Taking the fusee apart, we can see the ratchet mechanism used to wind it. ….Looks like those screws are a little loose. This would present a big problem if not addressed because those two screws effectively hold the entire power of the mainspring acting on the fusee’s gear. If they suddenly came loose or broke the mainspring would rapidly unwind and cause damage to at least itself if not other components. We’ll need to address this later.

The escapement on this clock is called a platform escapement (I believe) because it has its own separate plate or platform that can be removed from the rest of the mechanism for maintenance. The actual escapement geometry itself is a lever escapement.

I cleaned it in a watchmaker’s parts cleaner. Then re-oiled it.

Next I burnished all the pivots.

Now to fix those screws. On closer inspection, the threads were stripped so I drilled them out to a larger size and tapped in new threads to accept a slightly larger screw. Unfortunately I don’t have photos of that process, but in the end the ratchet was secured firmly to the fusee.

To make the new screws fit the countersinks in the holes of the ratchet I graved the countersink profile onto the heads of the screws, using the watchmakers lathe.

On the other side of the ratchet wheel is this stout steel spring. This is called the “maintaining power” spring (invented by the venerable John Harrison) and simply there to take up slack caused by the winding procedure. When the clock is being wound, the mainspring stops giving power to the clock. During those moments this spring, which is usually fully flexed in normal operation because it is weaker than the mainspring, comes into play and provides power to the train. From the perspective of all the wheels after this part then, the clock is always under spring power even when being wound.

In these videos you can see the little bit of flex the spring has.

And now reassembling. It’s a very simply train of gears, keeping time only.

Ticking again!

Here’s a video winding the fusee. Note firstly how the rope winds from the spring barrel around the fusee. Then also look for the “maintaining power” feature: the gear beneath the fusee always pushes against its pinion, in contrast to the ratchet and fusee just above it that jostle in the winding motion.

The trick of the fusee is that it allows the rope coming off the mainspring to pull on a different diameter as the spring lets out its power. The different diameters of the fusee counteracts the different power the mainspring gives off as it unwinds.

Per wikipedia: “The torque provided by a mainspring decreases linearly as the spring unwinds during a clock’s running period. The fusee’s purpose is to even out this torque.”

Much like a teacher grading on a curve, the curved profile of the fusee flattens out the declining performance of the spring. Very clever, in my opinion.

Another method to counteract the decreasing torque is to incorporate a mechanism that has a spring acting against the mainspring, pushing most against it when the mainspring is fully wound and less when it is closer to fully unwound. This is known as a stackfreed.

I’ll end with some fun illustrations by Leonardo Da Vinci of some fusees and stackfreeds.

Codex Madrid I fol. 13v (stackfreed)

Codex Madrid I fol. 16r. (fusee)

Codex Madrid I fol. 45r (fusee)

Codex Madrid I fol. 4r (fusee, note the use of square shaft to translate the rotation while allowing the linear movement of the pinion)

Codex Madrid I, folio 85r (fusee)

Leave a comment