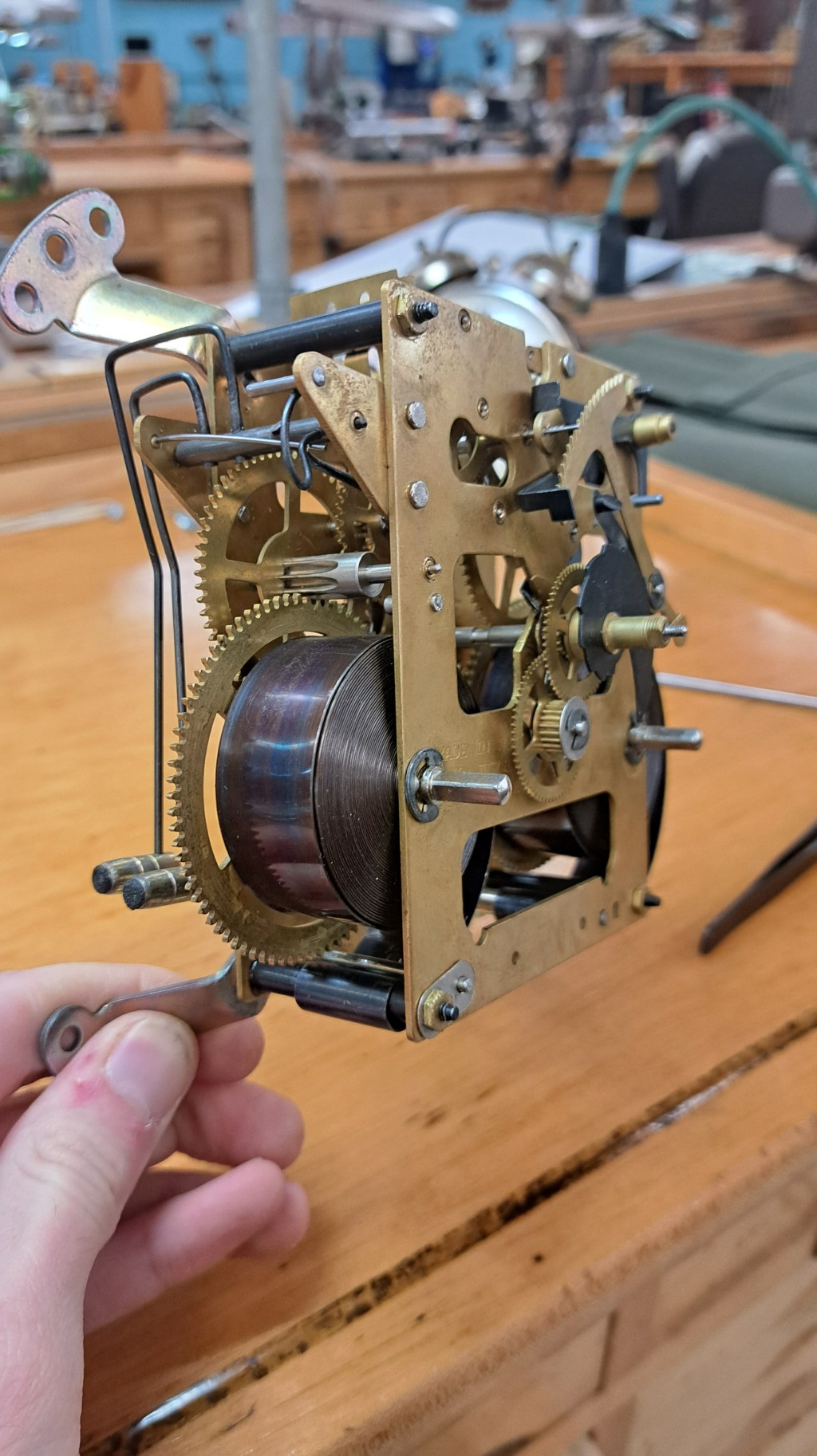

Here is a 31 day clock in need of repair. Something has stopped it from keeping time – could be it just needs new oil, the mainsprings have worn out, or something is causing friction like damaged gear teeth. Let’s see what we can find…

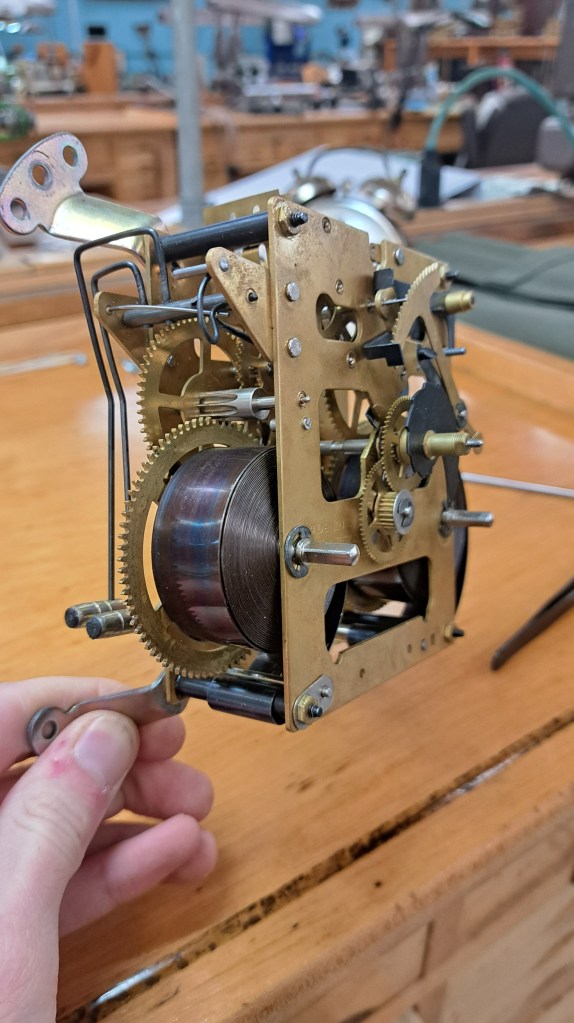

First I removed the movement from the case and examined it.

Next I let down the power by clamping the mainsprings. The clamps are the bits of round metal around the springs at the top of the above picture.

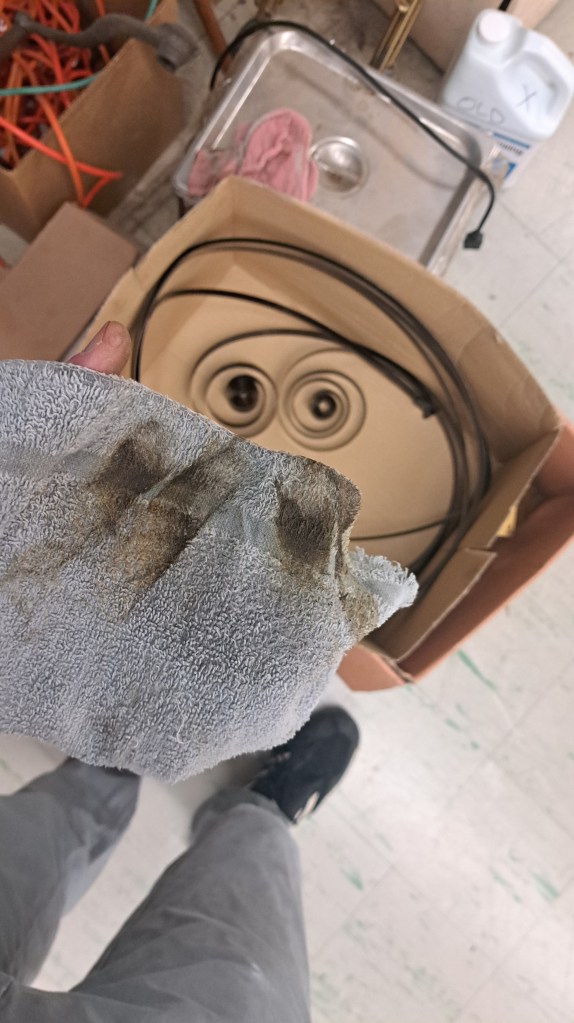

Then I disassembled it and gave all the parts a good cleaning in an ultrasonic bath, along with washing them by hand and drying with compressed air and heat.

Next I serviced the mainsprings by unwinding them. Because this clock is supposed to run for a whole month the springs are very long!

The old oil or grease has gunked up and was probably not helping the clock keep time.

I applied an appropriate amount of new lubricant.

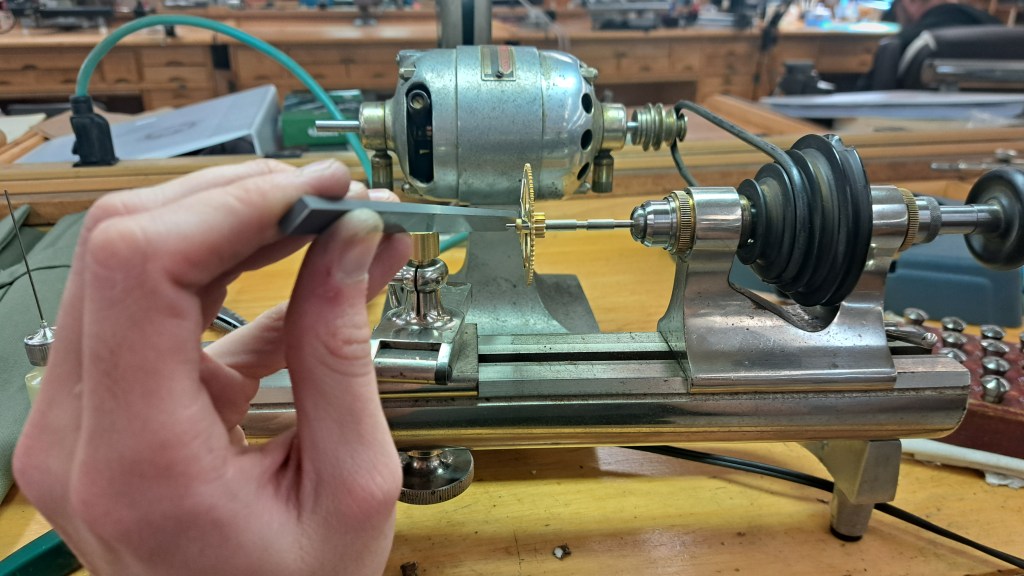

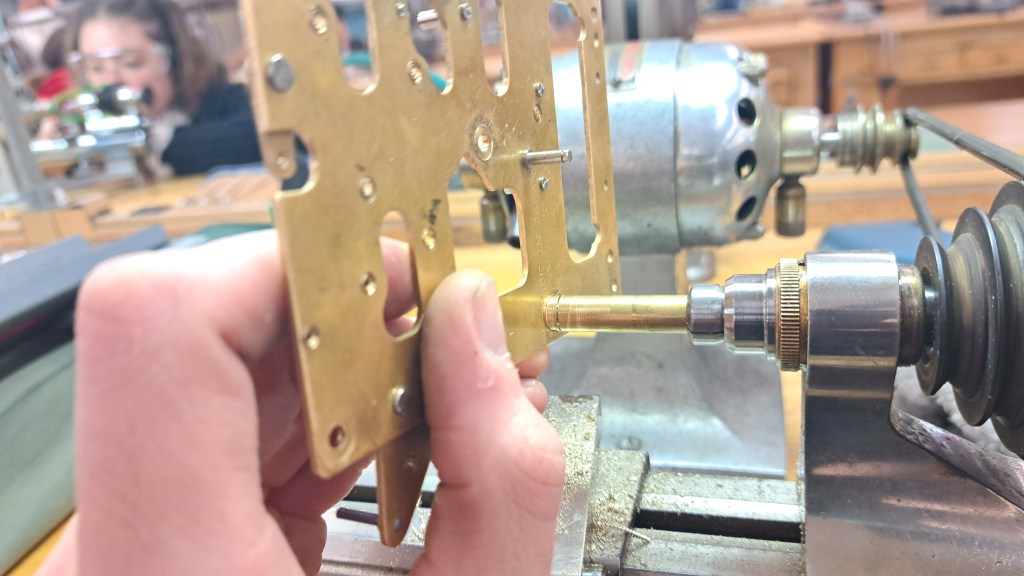

Then I polished and burnished all the pivots on the watchmakers lathe. In doing this I take out any scratches or rough spots which would have also added to the friction of the clock and could have resulted in its stopping.

Wear in the pivot holes can also add to friction because as the holes wear the resulting grit slows the rotation of the shafts and caused further wear.

The result is that some holes are oval shaped or out-of-round.

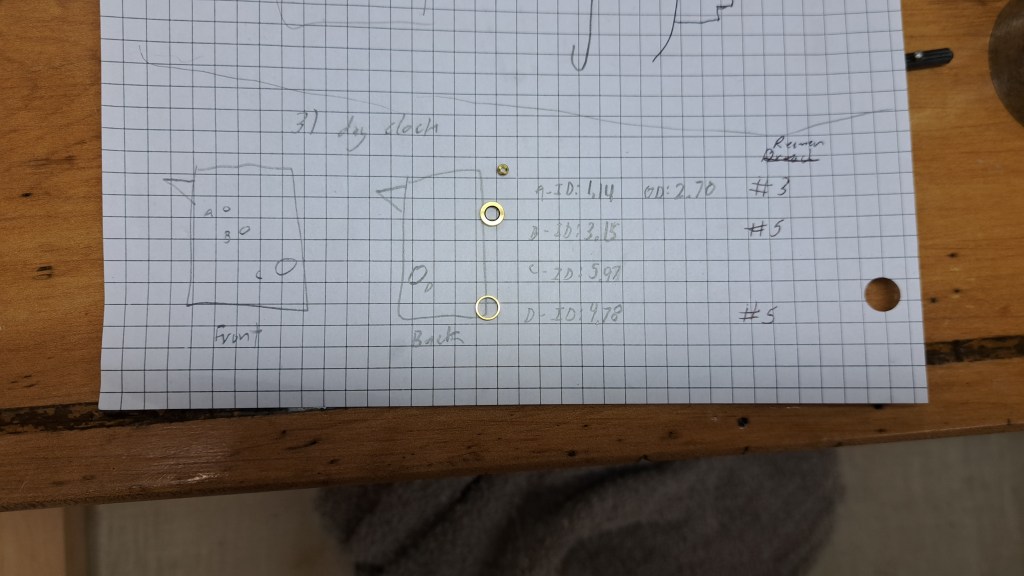

For some of the holes I could simply record what dimensions they should be and re-bush them with stock new bushings.

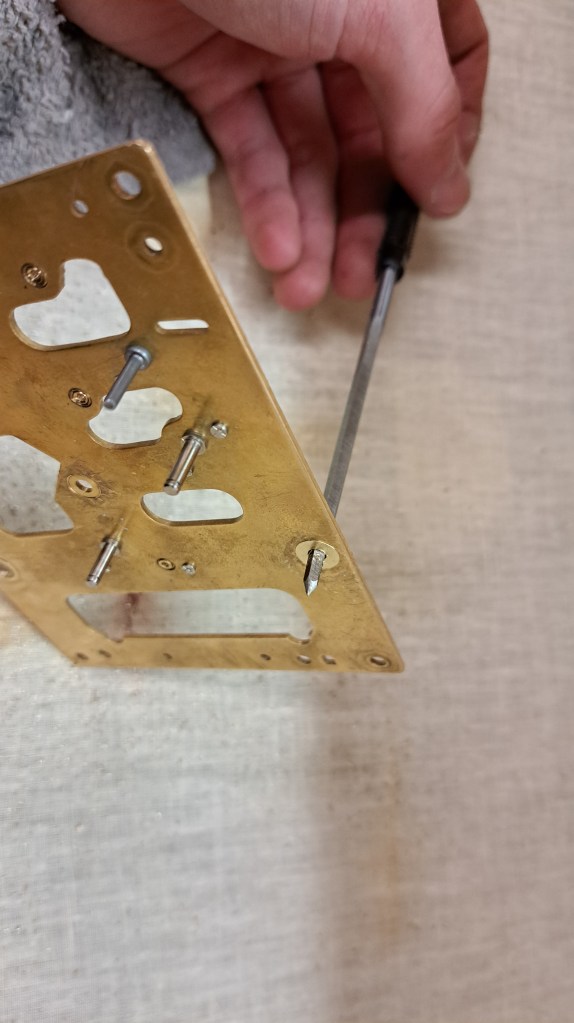

This process involved enlarging the old hole, trying as best as possible to preserve the original center, and pushing in the new bushings.

Above is the result.

But, two of the compromised holes were too large for new stock bushing so I had to make my own:

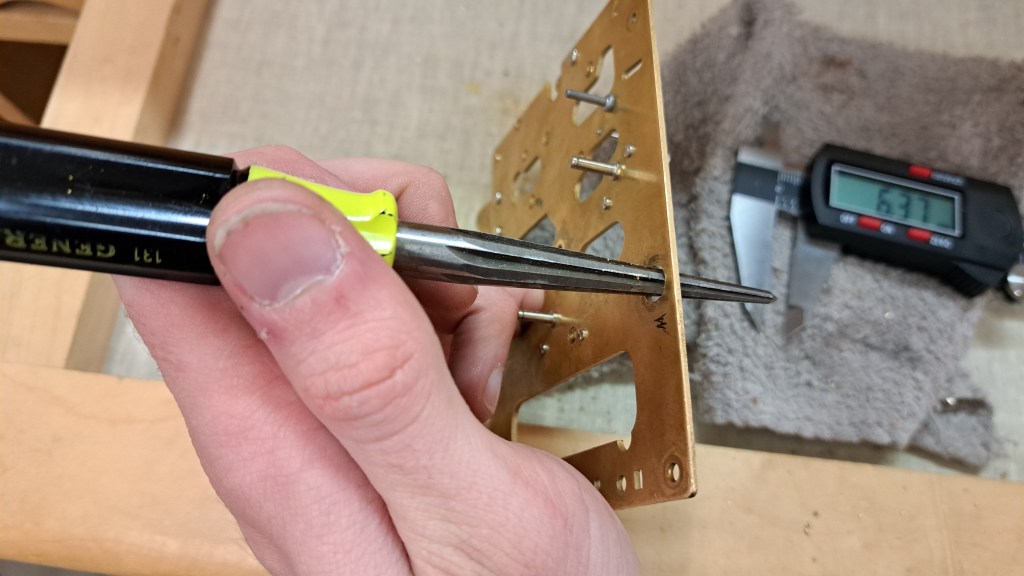

First I enlarged the hole with a reamer.

Next, on the lathe I turned a new plug or collar to fit in the hole and drilled a smaller hole in that new plug. I riveted this plug into place with a ball peen hammer (I forgot to take a photo of that).

I carefully made the hole in this new plug bigger using cutting broaches.

With those problems fixed I next looked for other things that might have resulted in the clock stopping.

I found a gear wheel that had begun to work itself loose on its shaft.

To solve this I removed the gear completely, enlarged its hole, and made a new plug on the lathe to fit that hole.

Because it will be transferring power this plug needed to be a secure fit on the shaft, so I took care riveting it on with a ball peen hammer (above).

Again with smoothing broaches I enlarged the hole to fit on the shaft; this time though I was looking for a tight friction fit so it would not slip of the shaft as it had begun to do.

Finally I hammered it home.

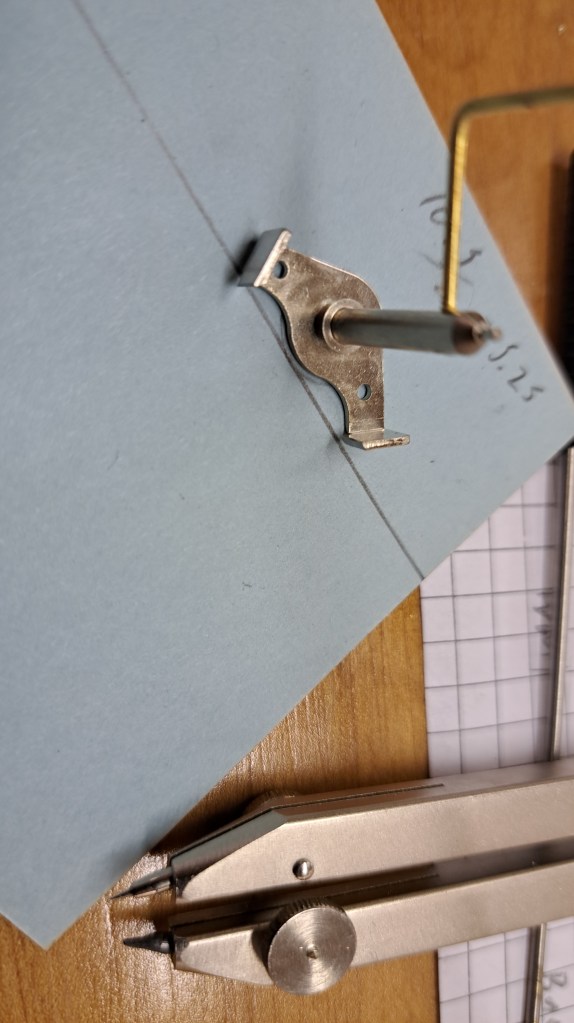

While I was doing that I noticed another problem with this part, which had probably caused the gear to work itself loose: some previous repairer had re-pivoted the shaft and in doing so drilled the hole for the new pivot off-center. See the below picture. This would cause the shaft to turn acentric and caused friction that, in testing, I believe was a critical problem stopping this clock.

I popped the old pivot out of its hole and cut a new one on the lathe to fit in it. I left the new pivot over-dimension.

I fit this plug into the off-center hole and then took the rest of the pivot down to dimension. This way it would be on-center with the rest of the shaft.

Another small thing I found is that the “star cam” on the shaft of the minute wheel which signals the strike on the hour and half-hour had excess solder on it from a previous repair.

This excess solder, most likely containing lead oxide, can wear off and act as grit which causes friction in the mechanism.

I cleaned it up.

Then I did some testing on the escapement to make sure it was working well.

Finally I reassembled the movement and tested it for a week or two before putting it back in its case.

So there were quite a few problems with this clock, from small things causing friction to bigger issues with pivots and gears. In such a delicate system it would be unwise to address just one of these problems hoping that it is the problem, because every part effects every other part so that if one is slightly out or wearing this causes ripples and problems that propagate to other parts.

Perhaps the pivots and pivot holes were wearing and this caused the acentric pivot to become a bigger issue such that its gear was now binding for one part of the rotation and this was working the gear loose.

Add to that the gunky grease on the mainsprings and old oil on the rest of the mechanism…

With a face, arms, hands, and a heart-beat the clock is apt for body metaphors, and I guess I find myself arguing for holistic treatment.

Leave a comment