Anniversary or 400 day clocks are simple because they just tell time – no chimes or strikes – but are also tricky because they are very sensitive since they are supposed to run for so long.

Here it is as I received it.

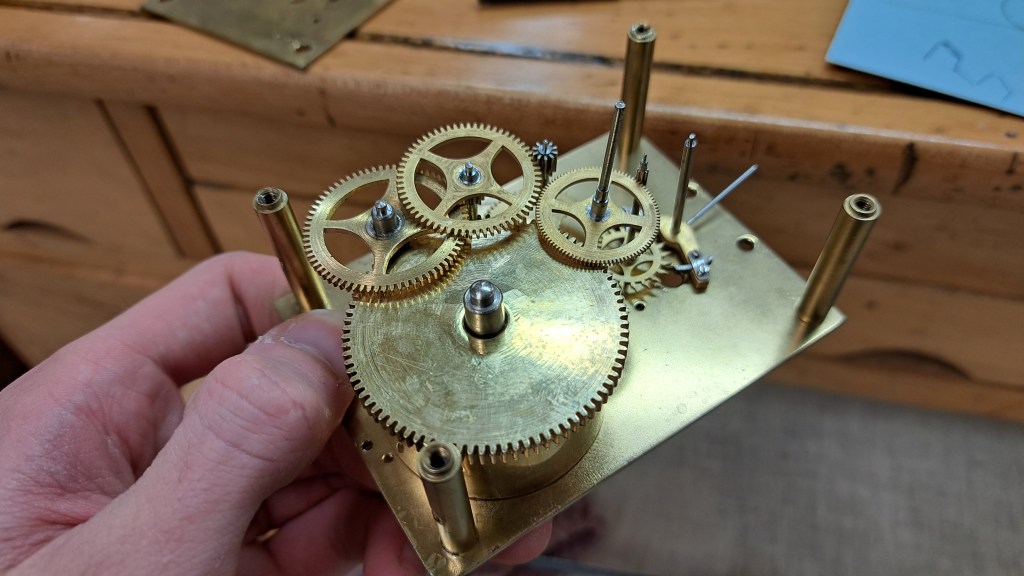

First I disassembled it. The movement really is simple, just one gear train from the mainspring barrel to the escapement.

Cleaning and checking the mainspring is extra critical in a 400 day clock because the movement needs all the power it can get. My instructor said that it is mostly standard to always replace the spring in a 400 day clock because any wear or tiredness in the spring means failure.

In preparing to clean the wheels I noticed one of them was in poor shape (I think from some previous repair).

I consulted a book to find the serial number and thus locate a similar movement so I could source a replacement wheel.

The replacement wheel came from a clock that was also in need of repair, and it turned out that this wheel was again the issue – though this time it was much easier to fix. One of the teeth was bent slightly and caused friction; in the photo, the guilty tooth it is on the lower wheel but toward the top of it, 2 or 3 teeth to the left of the pinion. I carefully bent it back and checked it ran smooth.

I cleaned the parts in an ultrasonic cleaner.

Burnished the pivots on the watchmakers lather (forgot to take a picture), and smoothed the pivot holes.

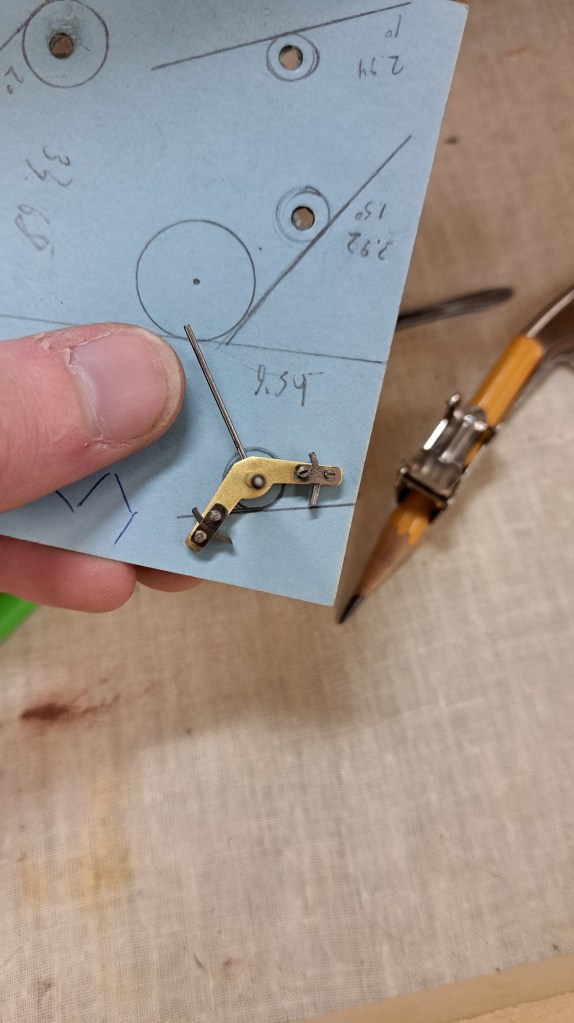

Checking the pallet geometry.

The escapement working well is critical in such a sensitive clock so I carefully checked the “locks” and “drops.”

Reassembly.

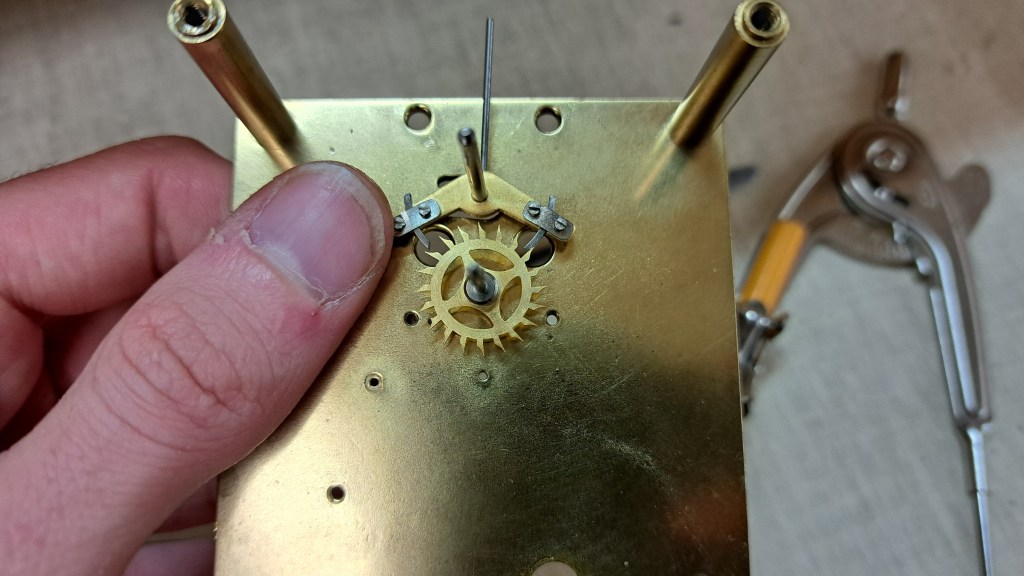

The escapement wheel gives just a small flick of energy to the pallet which will send the balance rotating.

It’s just the smallest movement, but the escapement wheel does push the pallet/anchor back and forth a little – and hopefully enough!

Here it is all put together.

I’m amazed that the spring slowly unwinding and pushing that pallet can cause the mass to rotate for more than a year!

Leave a comment