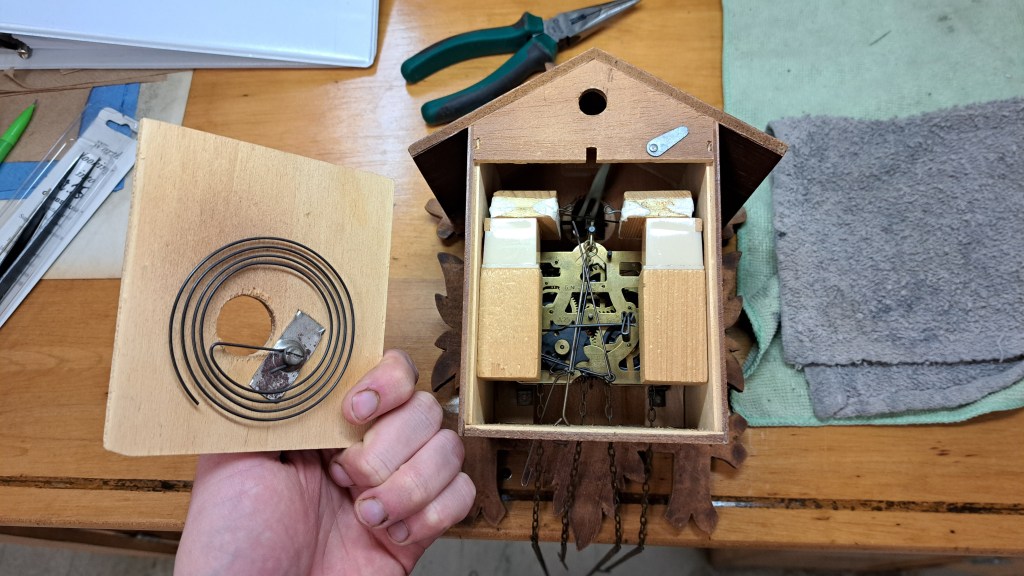

Here’s a charming little clock. It’s a fairly simple cuckoo clock with a 1 day, 2 weight “Regula” movement that needed a bit of cleaning and servicing to get it singing again.

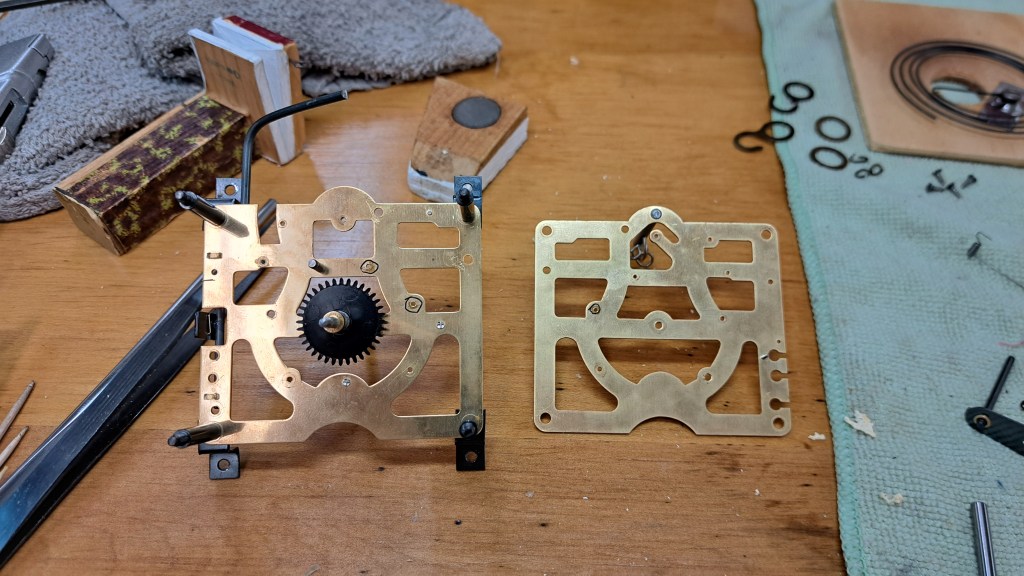

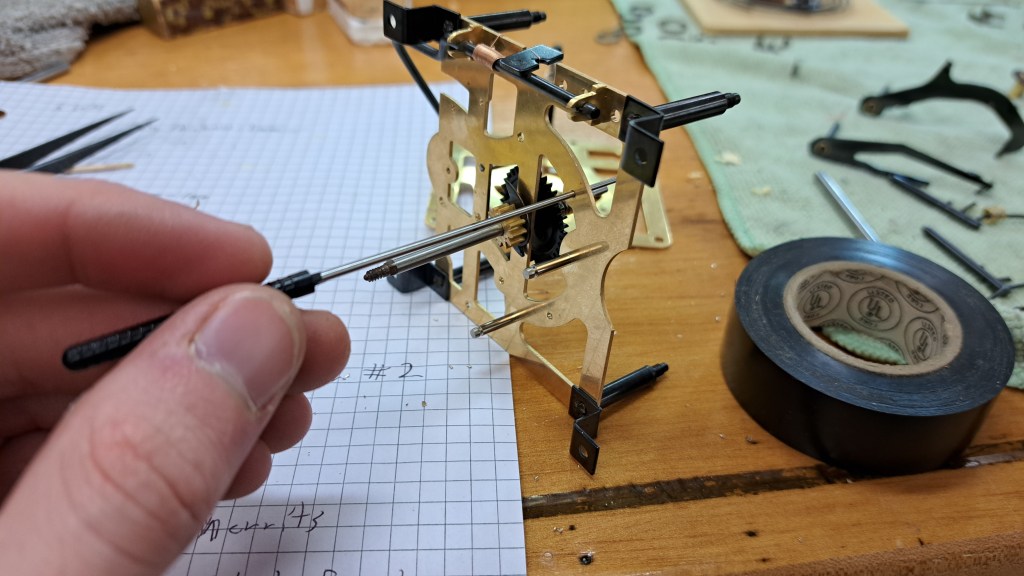

Movement removed from case.

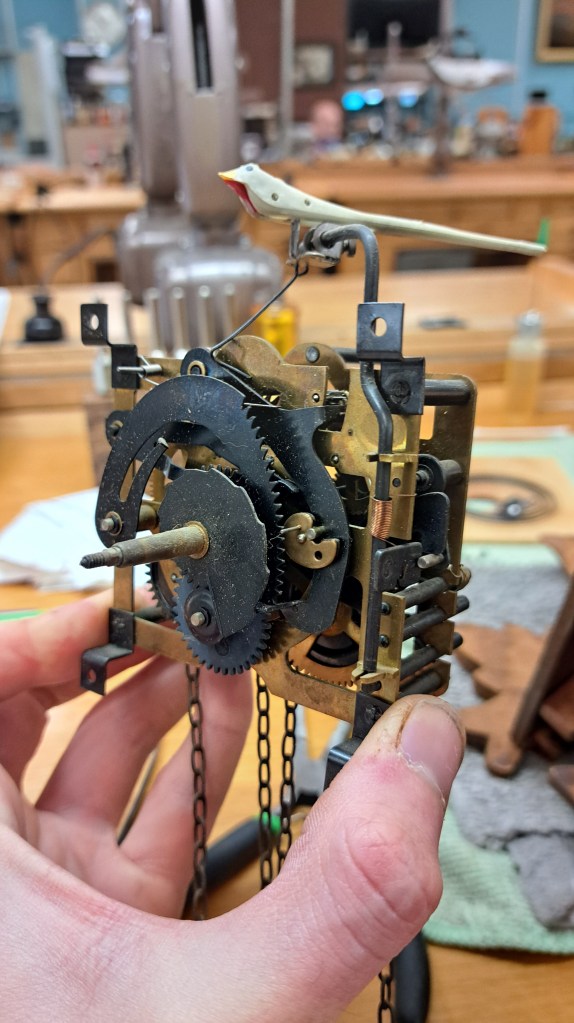

I love how simple and effective the beak mechanism is. When assembled, a wire protruding from one of the bellows pushes on the bird’s elongated tail-feathers, as I’m doing with my fingers in the video. This causes the bird to lean forward and open its beak in song.

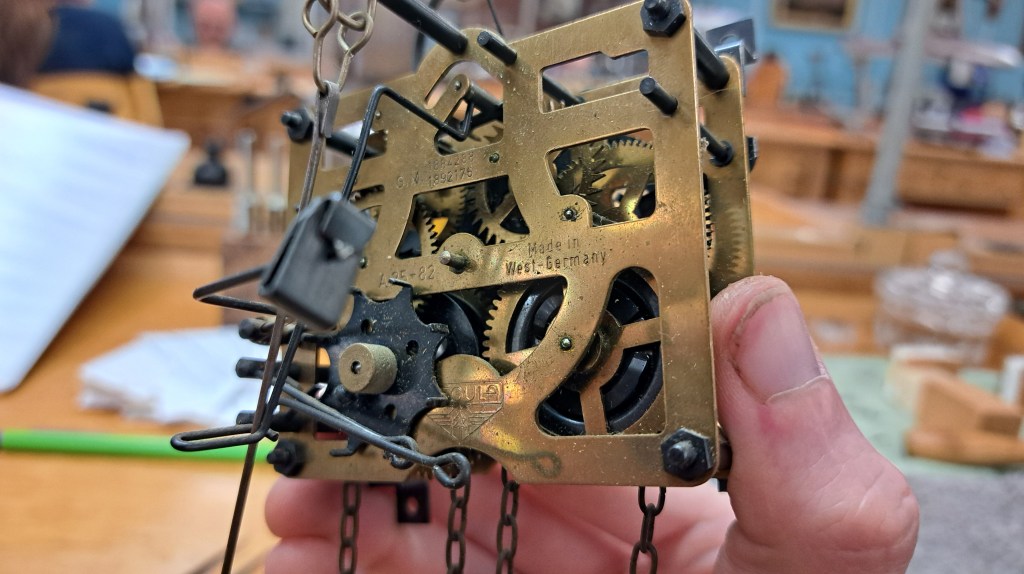

Well we can certainly date this to between 1949 and 1990.

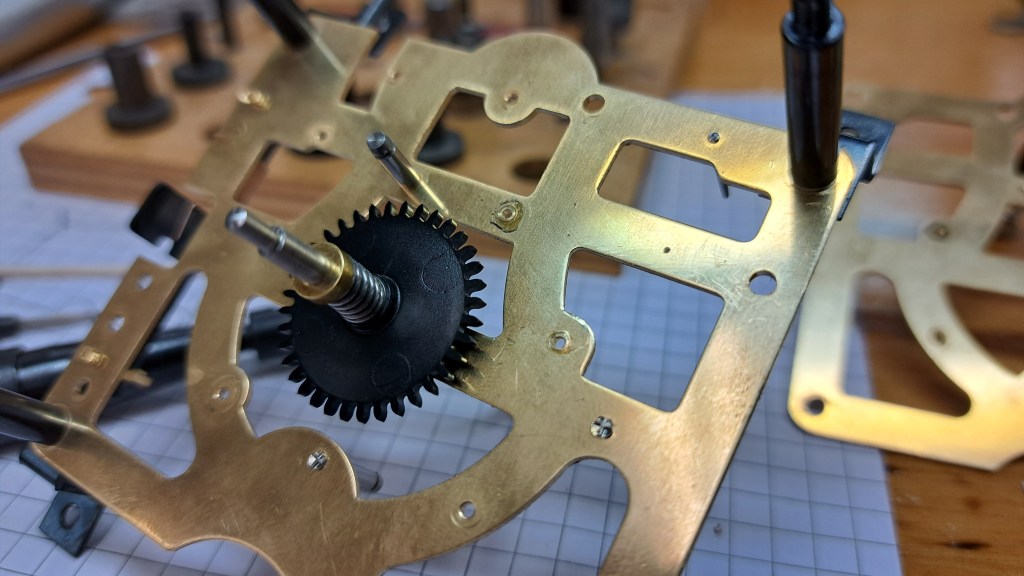

Note the star or crown looking wheel in the bottom left. That is the critical part of the cuckoo side of the clock because when it rotates (on the hour and half hour), it causes those levers to move up and down. The levers are connected to the bellows and cause the cuckoo call as well as the bird motion.

I then acquainted myself with the mechanism and disassembled it. Next I gave most of the parts a wash in an ultrasonic cleaner, followed by water and a toothbrush, then drying with air and a hotbox.

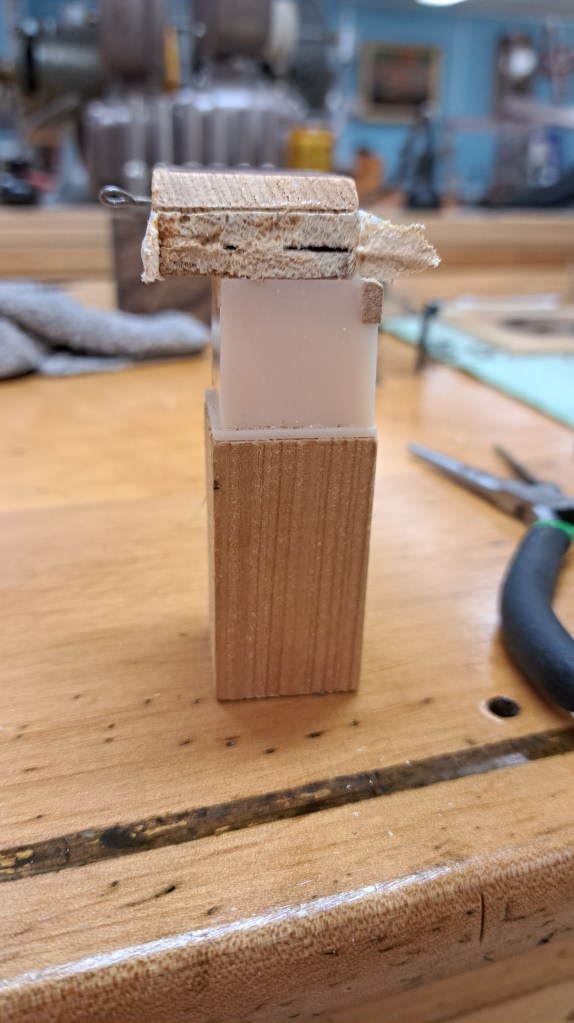

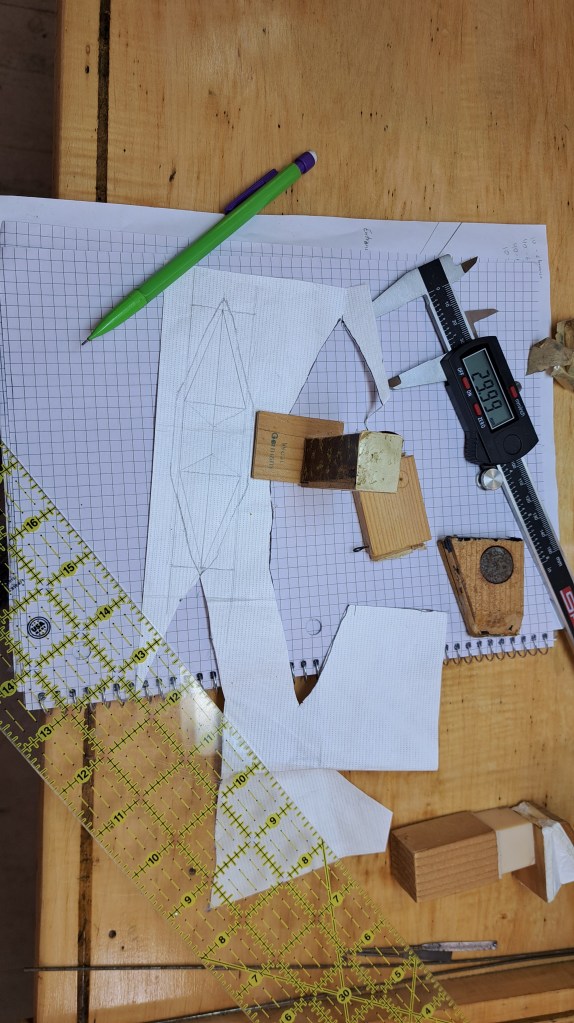

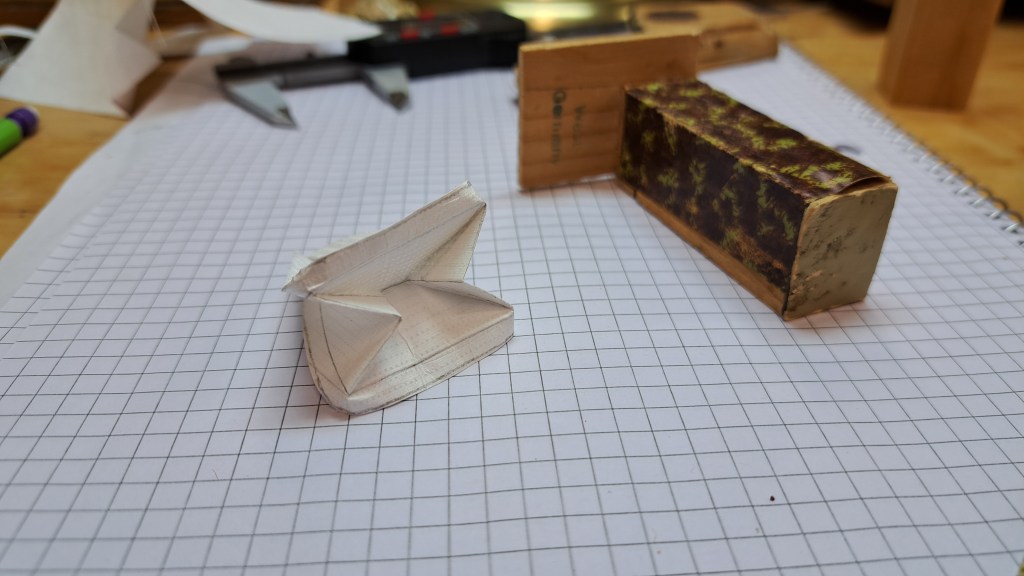

One of the bellows needed a bit of work. While the main diaphragm was in good condition, the ‘hinge’ was torn so I cut a new one and glued it on.

For practice, my instructor also had me fix a couple of other bellows – here’s some photos of that:

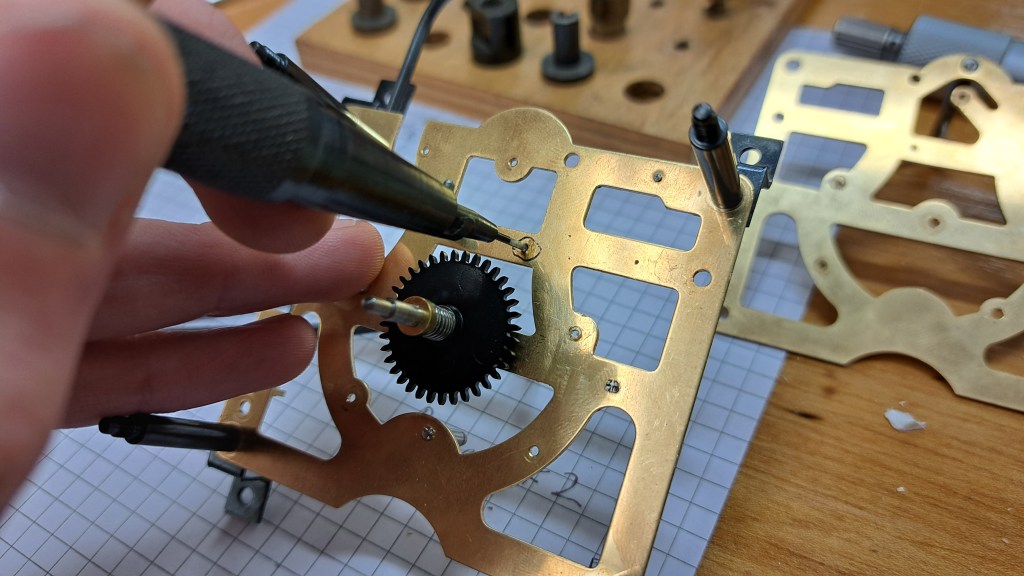

Back to the clock, I polished all the pivots in a watchmakers lathe:

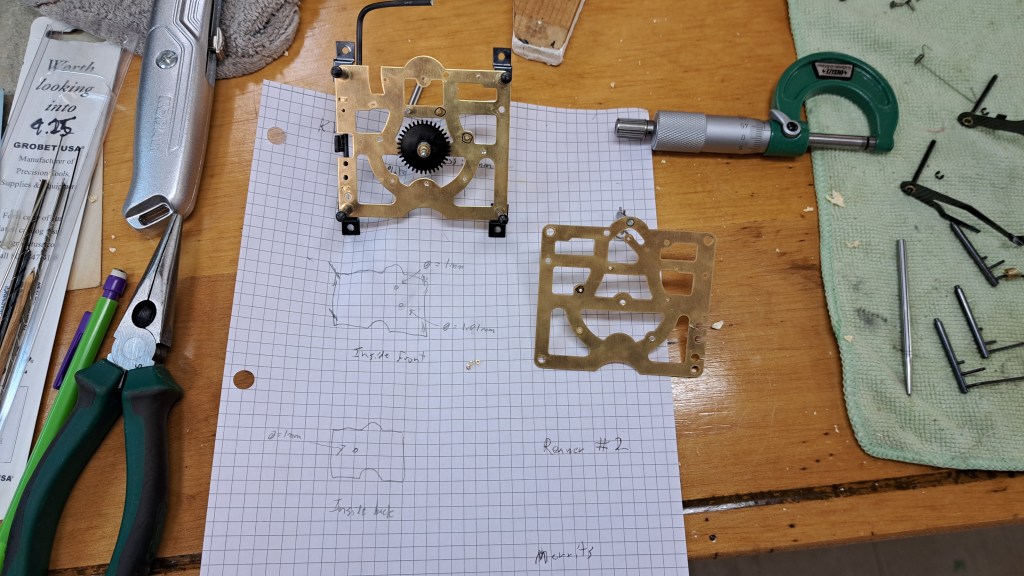

Next I inspected the holes in the plates that the pivots ride it. Two of them, circled in black sharpie, exhibited excessive wear and called for replacing.

Here is a close-up of a pivot hole needing bushed. It might be hard to tell, but it is slightly out of round – more in the shape of an oval. This is caused by the pivot grinding more into one side of the hole than the other. Addressing this is critical because if left untreated the wear will only get worse as it further erodes and grit produced from the erosion exacerbates the issue, causing more and more friction and eventually miss-alignment of parts.

Bushing or re-bushing involves reaming out the old hole and fitting a new tube with a properly sized pivot hole. Bushing are standard parts in the clock making trade. The real trick is enlarging the old hole in a way that keeps it centered on the original pivot location and not biased toward the direction the pivot wore in. This is done by making the reamer cut mostly in the direction opposite the wear. It requires a bit of “feel” and I previously practiced doing just that procedure.

Hopefully in the above picture you can see the two new bushings pressed into place.

Then I gave all the holes a clean with peg wood and smoothed them with smoothing broaches.

Reassembled movement: note how much cleaner it looks compared to at the beginning.

After testing the escapement, re-housing the movement, fitting the bellows back in place, and setting the linkages all up the cuckoo finally came back to life!

I’m learning that Cuckoos have had a kinda outsized mark on human culture: sacred to the Greek Goddess Hera, the Hindu God Kamadeva, associated of course with time, especially springtime, but also with madness and craziness [calling someone a cuckoo], we also get our word cuckold from them, and these birds show up all over the place in art.

I like that by combining Cuckoo with clock something can be associated both with freedom and regularity, both divine or whimsical nature and rote to-man’s-ends nature, and keep sentimentality and un-sentimentality at or to the same time:

“Wouldst thou be taught, when sleep has taken flight,

By a sure voice that can most sweetly tell,

How far off yet a glimpse of morning light,

And if to lure the truant back be well,

Forbear to covet a Repeater’s stroke,

That, answering to thy touch, will sound the hour;

Better provide thee with a Cuckoo-clock

For service hung behind thy chamber-door;

And in due time the soft spontaneous shock,

The double note, as if with living power,

Will to composure lead — or make thee blithe as bird in bower.”

– Wordsworth, “The Cuckoo Clock,” 1842

Leave a comment