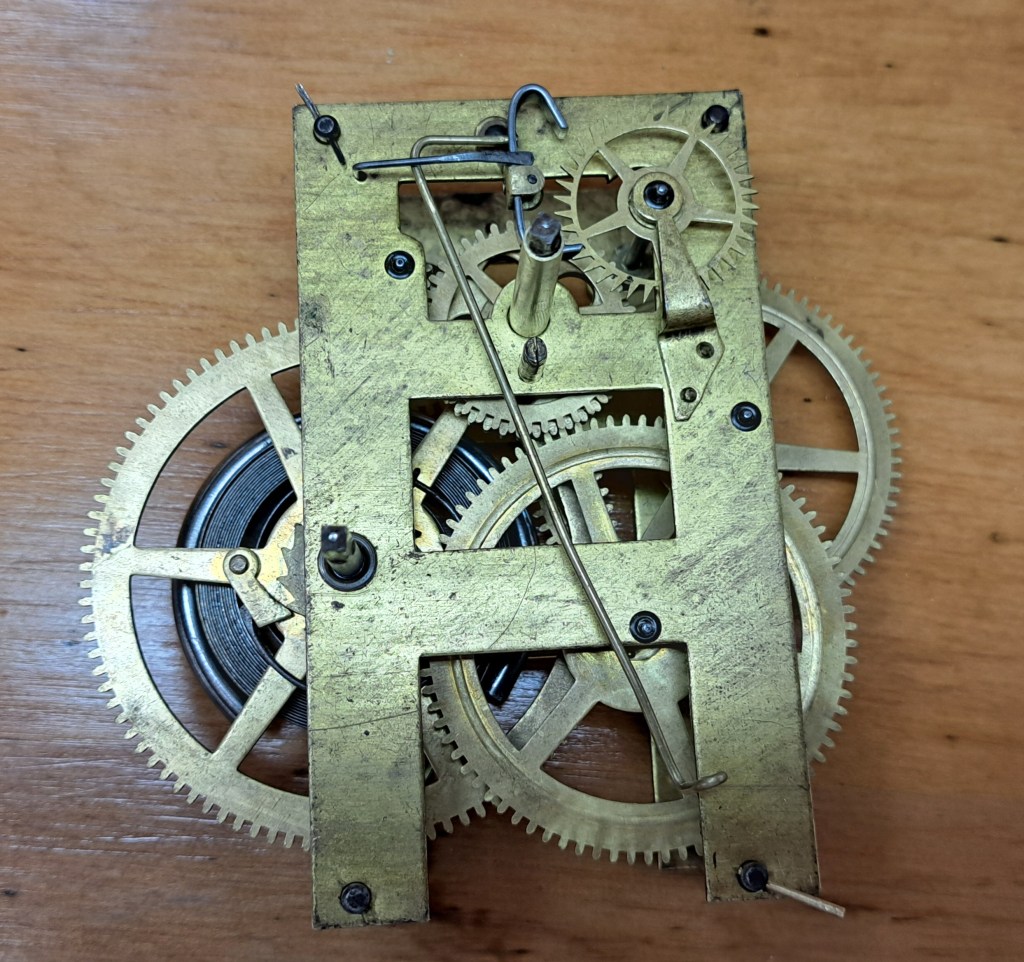

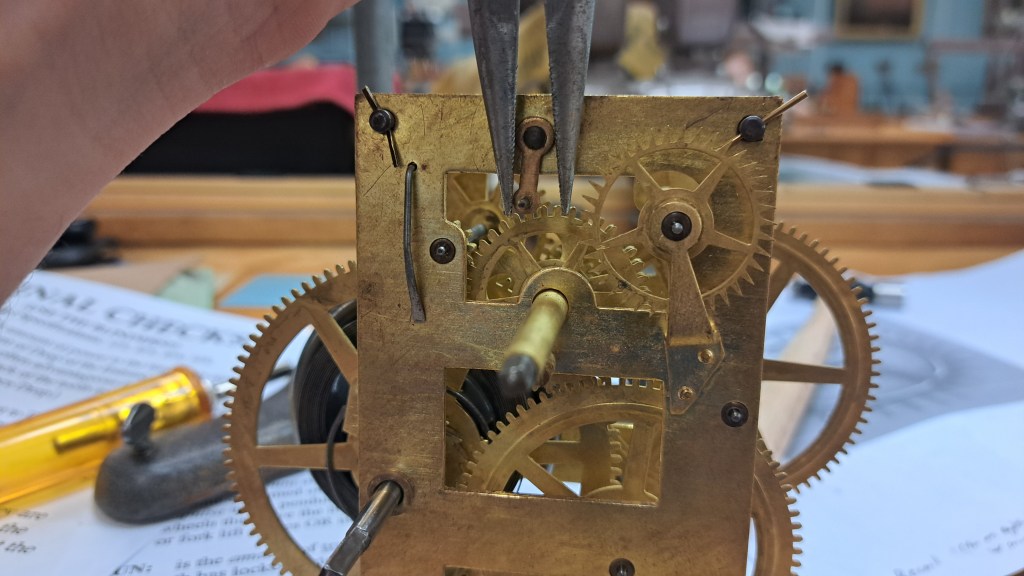

This is an American time-only clock movement. It’s very simple because it only gives hour and minute, no bells or whistles.

First I put a clamp over the spring and let down the power so I could safely take it apart.

I cleaned the parts in an ultrasonic cleaner and by hand with a toothbrush.

I polished all the pivots, and reground them where necessary, on the watchmakers lathe.

Then I cleaned the bushings with peg wood (basically a toothpick), and burnished them with smoothing broaches. None of the bushings had excessive wear so I did not need to replace any.

I cleaned and re-oiled the mainspring.

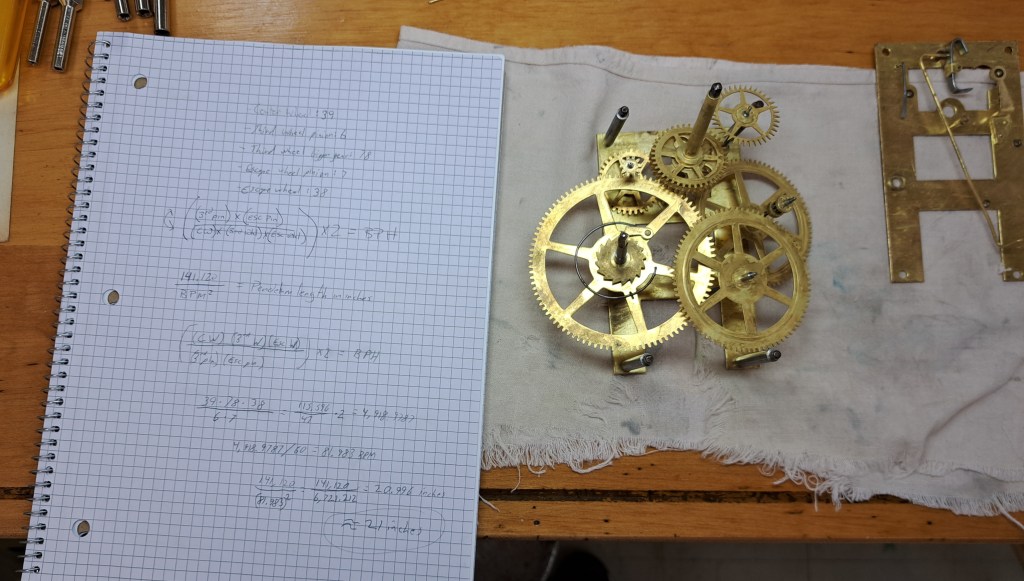

To practice, I calculated the theoretical length of the pendulum to be 21 inches. This turned out to be too long.

I reassembled everything and gave all the pivots a small amount of oil.

Making a new strip pallet:

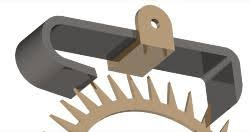

This escapement is a recoil type with a strip pallet. The strip refers to how the anchor is formed from a bent ribbon of metal. The trained eye will likely have noticed that the anchor for the escapement on this clock is atypical. Namely, the strip is on the wrong side of its pivot.

Compare this:

To what we have:

So I made a new one by first cutting a new flat strip of steel.

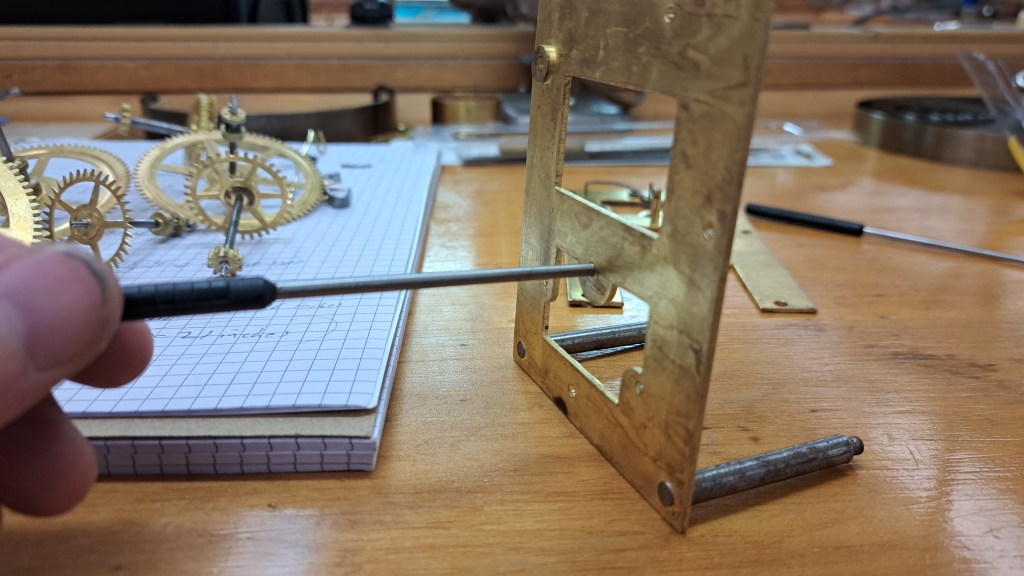

I drilled some holes and then riveted the pivot saddle on.

Getting the bends right is tricky, but critical to making it tick – literally.

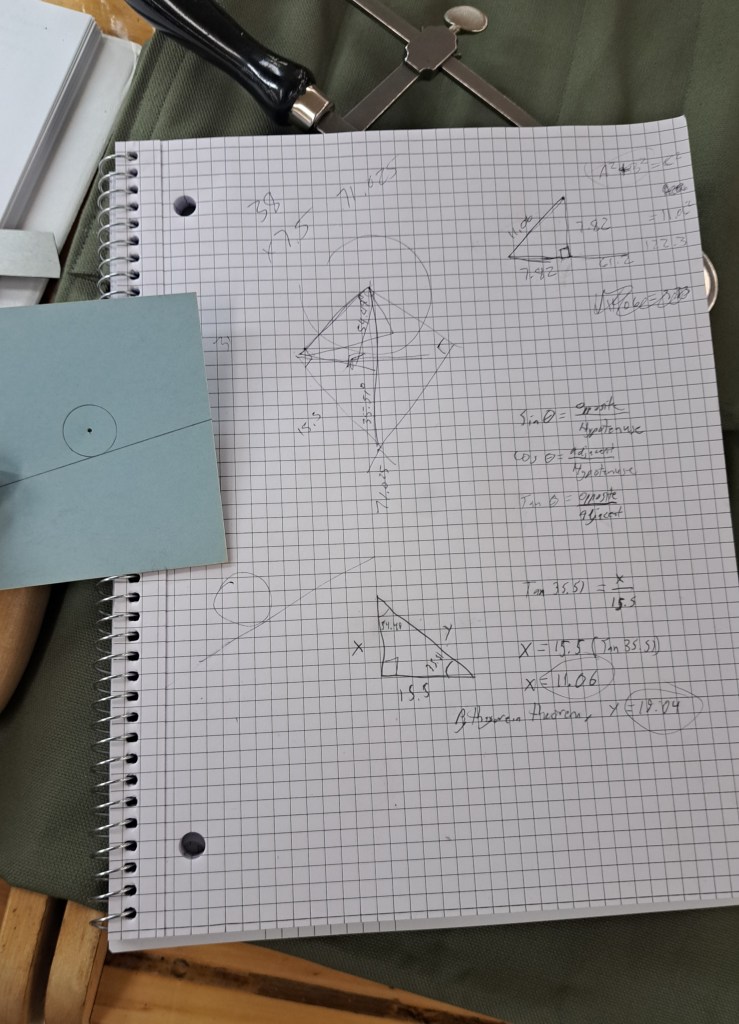

I did some geometry to get an idea of the ideal bends, but it came down to a lot of educated guessing, checking, and tweaking.

Shifting the pivot location was also necessary to get the geometry right.

When it was finally ticking well I polished the pallets to cut down on friction and make the clock run longer.

At last it ran smoothly with not too much “drop” (free rotation of the escapement wheel) and an even beat. The escapement wheel is slightly out of round, so it was impossible to get a perfect tick-tock, but it runs pretty well!

Leave a comment