I have been learning clock repair for about two weeks now. This is a post just about some beginning exercises. Later posts in this series will cover only one topic.

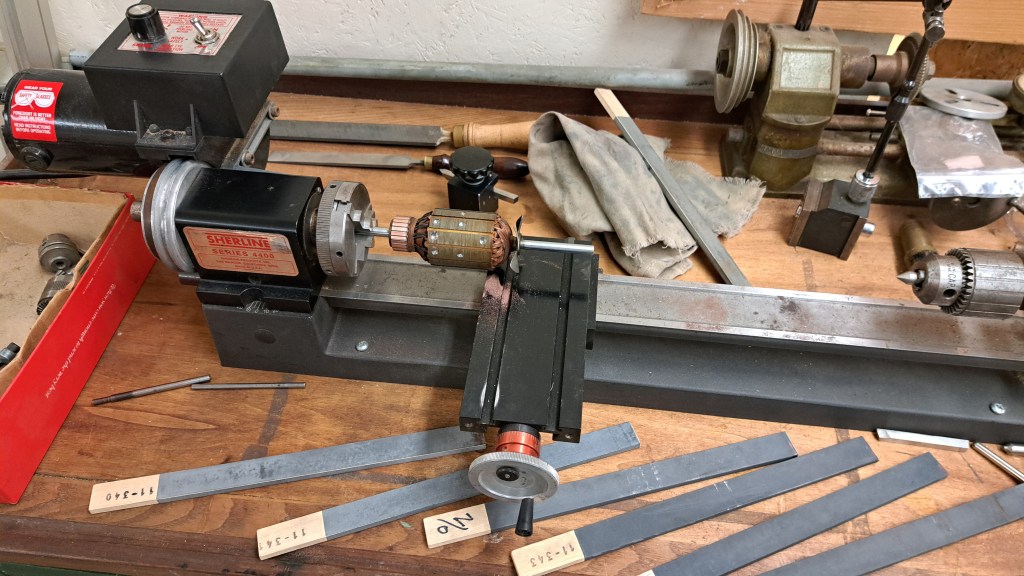

Firstly, here are some of the tools I’ve been learning to use:

File Exercises and Heat Treating:

I was given some stock and tasked with filing them to look like example tools.

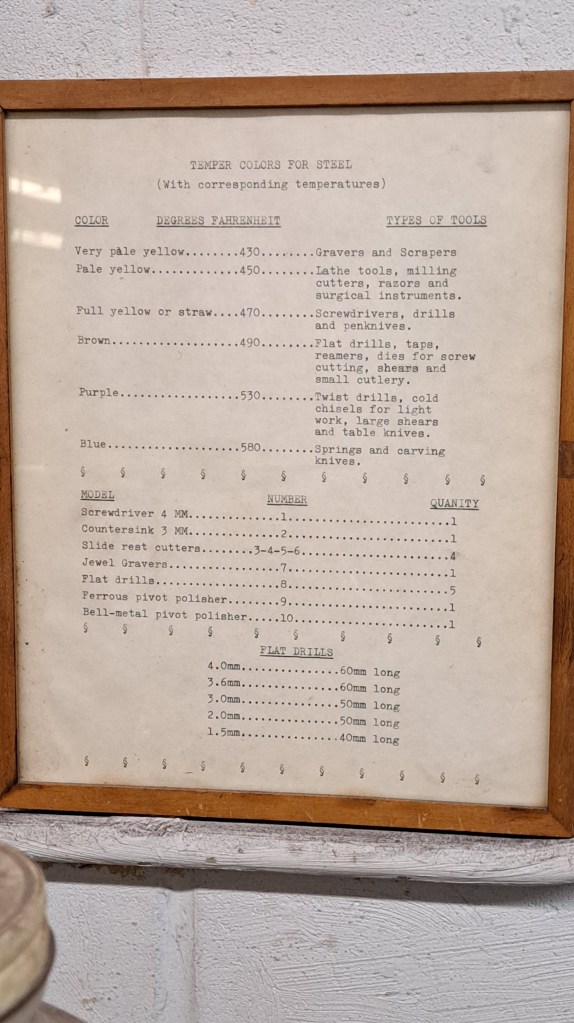

After polishing them with the buff sticks, I learned how to heat treat them by first getting them red hot (very hard but brittle), then tempering them back.

Different tools got different tempers. This screwdriver was tempered till purple, or ~530 degrees.

Finished parts after final polish.

Watchmakers Lathe:

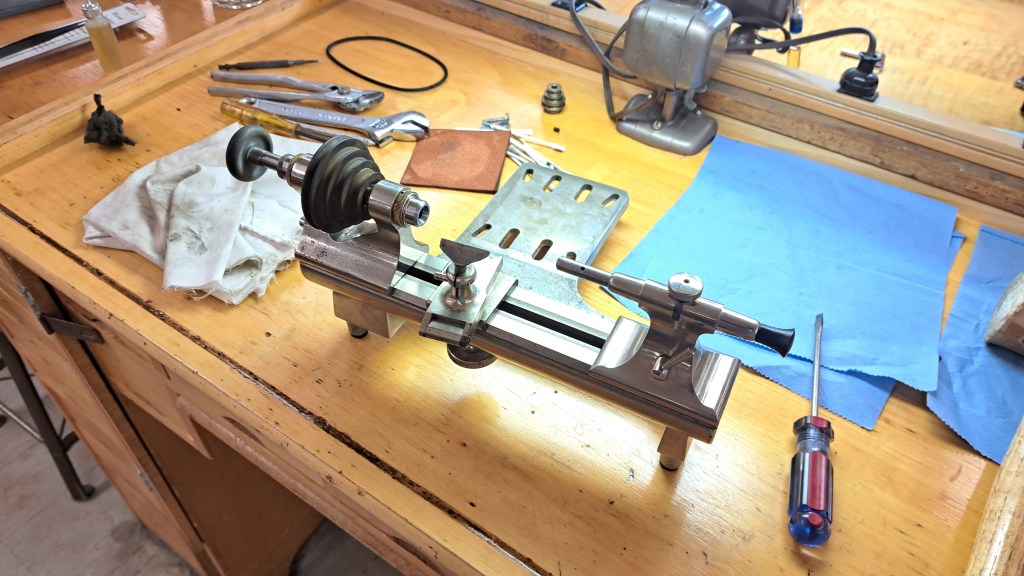

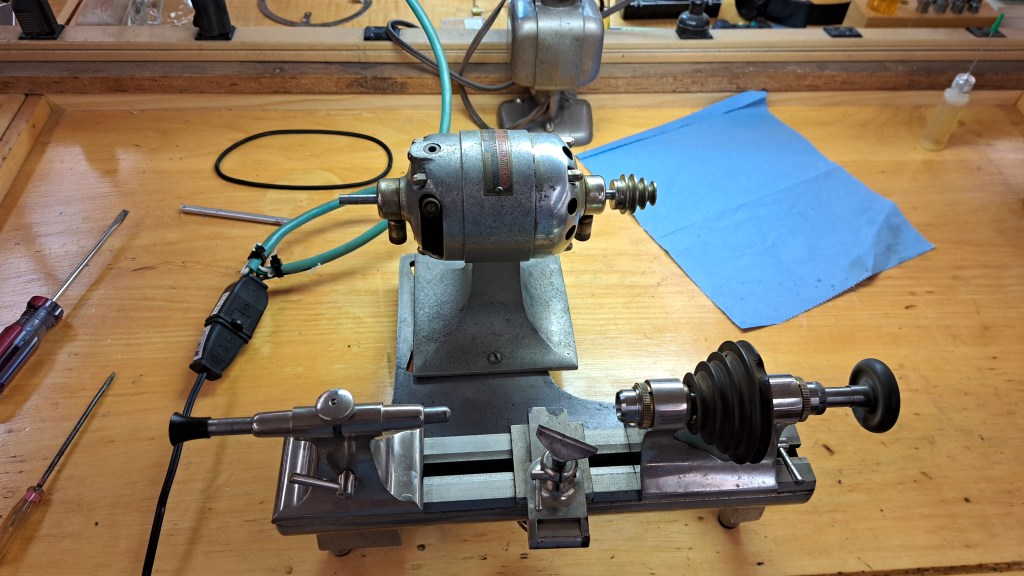

Next I cleaned a watchmakers lathe and restored the motor.

The copper on the commutator had to be reground and polished.

Finally, I set it up for left-handed use.

Leave a comment